|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-82436 (OS)

Gages:

Accuracy

Size

Range

Full Scale

Dia.

A

0-1250

6 in.

B

0-5000

6 in.

C

4 in.

0-25

Relief valve:

Cracking pressure, 4500 100 psig

Accumulator:

Size, 10 cubic inches; test pressure 8000

psig minimum

Working fluid supply: Capable of supplying to the pump

a 5 percent solution, by weight,

of water-soluble oil in water at

a rate of 2 gpm at 7 3 psig and

at any temperature between +32

and +98 F

Drive unit: 5 horsepower synchronous electric, nominal

Outlet filter: 25 micron maximum, 5 square inches of screen

area minimum, 4000 psig minimum working

pressure

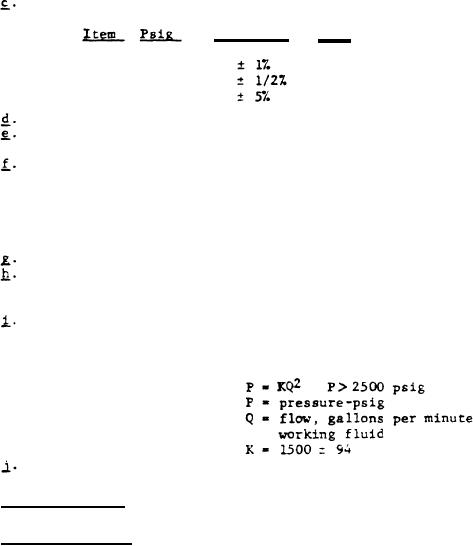

Orifice, flow-limiting:

The fixed orifice, when connected

in the test set-up, Figure 3,

shall produce a flow rate as de-

fined by:

Inlet filter:

50 to 80 micron

4. 5.4

Test procedures.

4.5.4.1

Operational test.

The pump, containing twenty cubic centi-

meters of oil, see 6.7, shall be mounted in the test stand and connected

the auxiliary equipment. Prior to testing, the flow rate shall be preset

to

as folows: remove the Adjusting Screw Nut (Figure 1), apply a pressure Of

300 10 psig to the bias port. With the pump being driven at 3880 10

rpm, set the inlet pressure to 7 3 psig. Position the Valve Adjusting

Screw (Figure I) to obtain an outlet pressure of 2775 10 psig. Replace

the Adjusting Screw Nut and secure with a lockwire. The pump shall be

operated in accordance with the sequence indicated in Table XI. The pump

shall deliver the working fluid at the pressures specified in Table XI,

when the pump is driven at 3880 10 rpm, bias pressure is controlled within

the respective parameters and the inlet pressure in maintained between 4

and 10 psig. The orifice shall not be by-passed thus unloading the pump

during the test.

18

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |