|

|||

|

|

|||

| ||||||||||

|

|  MIL-P-82442(OS)

4.5.4.2

Operation. Install the pump in the pump test stand and

connect the applicable fittings in accordance with Figures 1 and 2. With

the pump operating at 3880 10 rpm, inlet pressure of 15 2 psig, the

output pressure shall be: 265 psig minimum. The pump shall be operated

for 1.5 minutes on tap water. Post-test servicing and maintenance shall

be performed in accordance with 4.5.7.

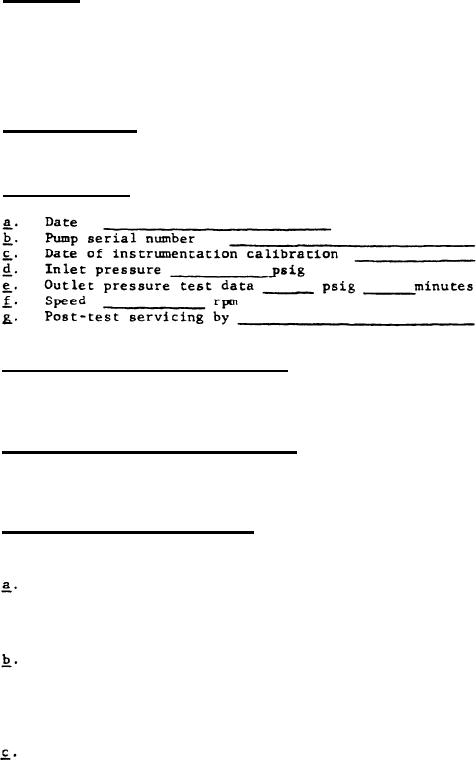

4.5.5

Test data sheets. All test data shall be recorded on data

sheets by the supplier. Data sheets shall contain, but are not limited

to, the following information:

PUMP, SEA WATER

4.5.6

Determination of defect or failure. Failure of a pump to

successfully pass the tests of 4.5.4.1 and 4.5.4.2 shall be cause for

rejection of that pump.

4.5.7

Pose-test servicing and maintenance. The pump shall be

disassembled and cleaned after each run. All packing preforms shall be

inspected and replaced if required. The pump shall then be reassembled.

4.6

Periodic production inspection.

Periodic production samples

The samples shall be tested

shall be selected in accordance with 4.3.2.

in accordance with the following plan:

The Sample of 1 unit from the first group of 30 units

will be called the first Sample and will undergo the

tests of Table IX for Sample 1. The sequence of tests

will be as shown in Table XX.

The Sample of 1 unit from the second and third groups

of 30 units will be called the second and third Samples

and will undergo the tests of Table IX for Samples 2

and 3 respectively. The sequence of tests will be as

shown in Table IX.

The next Sample will be selected from the next group of

units regardless of whether the shift to Step 2 was

made. This sample will be called the fourth sample and

will undergo the tests of Table IX for Sample 4, etc.

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |