|

|||

|

Page Title:

Table 1. Requirements and test procedures |

|

||

| ||||||||||

|

|  MIL-Q-48535A(AR)

demonstrate that the effectiveness of the proposed alternative(s) is

equal to or better than the specified quality assurance provisions

In cases of dispute as to whether the contractor's . proposed

herein.

q

q

alternative(s) provide equal assurance, the provision of this

All approved alternative inspection

specification shall apply.

provisions shall be specifically incorporated into the contractor's

quality program or detailed inspection system, as applicable.

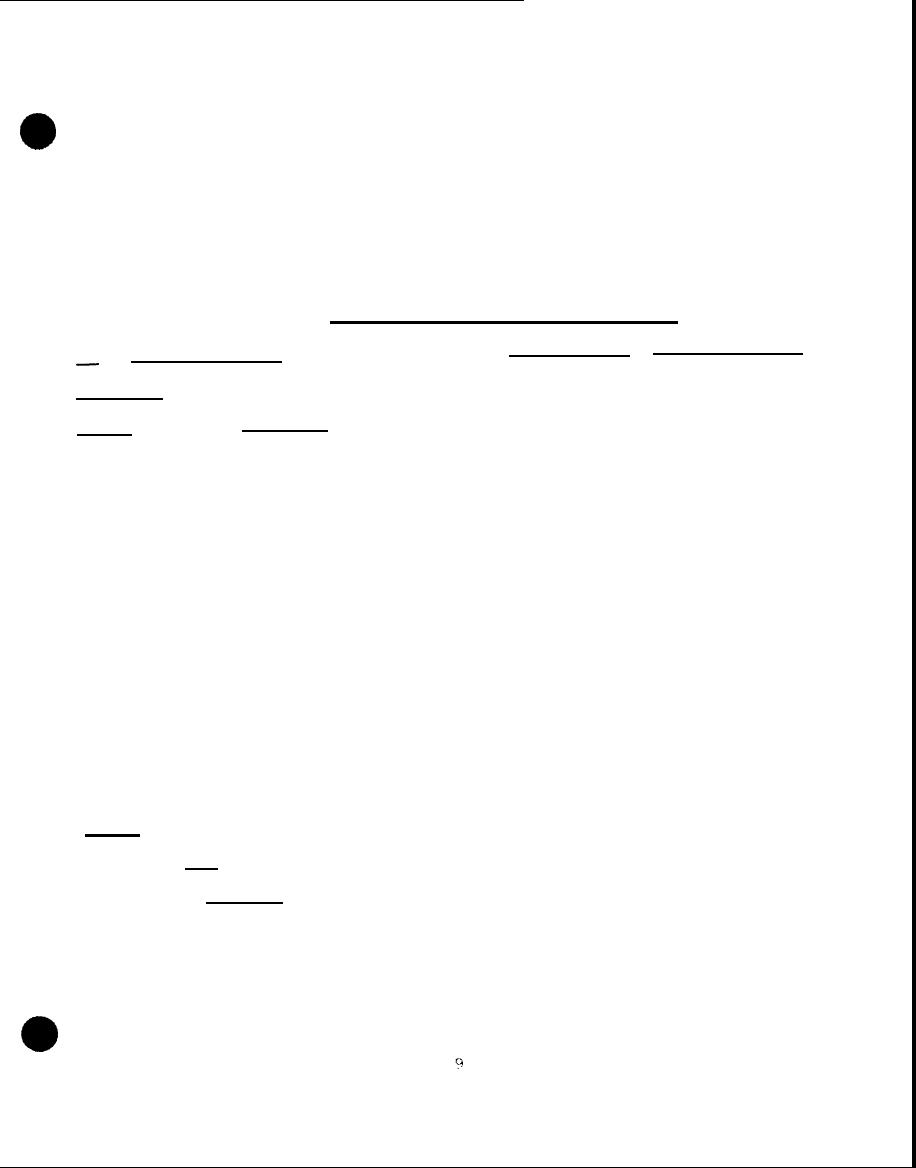

Requirements and test procedures.

TABLE 1.

Test procedure

Requirement

Characteristic

No.

None

Critical:

100% Inspection

Major :

4.12.4

3.6.5

Vibration "B"

101.

4.11

3.8.1

Cleanliness r defects

102.

4.7.1.2.1

3.10.1.1

Excursion ranger elevation counter

103.

4.7.1.2.2

3.10.1.2

Excursion ranger correction counter

104.

4.7.1.3.1

3.11.1

Accuracy, elevation readings

105.

4.7.1.3.2

3.11.2

Backlash

106.

Correction counter setting-affect

107.

4.7.1.3.3

3.l1.3

on elevation counter

Correction counter setting-affect

108.

4.7.1.3.4

3.11.4

on elevation level bubble

4.8.1

3.12.1

0

Operability torque (+60 to +90 )

109.

3.13

Counter numerals

110.

4,10.1

3.14.1

Illumination, level vial

111.

4.10.2

3.14.2

Illumination, COUnterS

112.

4.13

3.15

Interchangeability

113.

4.14.1

3.7.1

Sealing

114.

4.14.2

3.7.2

Purging

115.

4.10.3

3.14.3

External tritium contamination

116.

11729530

3.4

Fabrication

117.

4.15

5.1

Packaging

118.

None

Minor :

Special

sampling.

4.4

4.4.1 GeneraL. Subsequent to meet ing the requirements of Table

shall be Selected at random by a Government

I, three quadrants

each 50 produced or from

representative as a special sample from rs first. The samples shall

each month's production, whichever occu

e II and shall meet the

meet the requirements and tests in Tabl

pt characteristic 101, after

requirements and tests in Table I, exce

being subjected to Table 11 testing.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |