|

|||

|

Page Title:

Table III. Storage and operating temperatures |

|

||

| ||||||||||

|

|  MIL-Q-48555A(AR)

visually and tactually examined to assure conformance with the

requirements of 3.12.1. Following completion of sequence 3 and 5

soak periods. (room temperature), the quadrant shall meet all the

requirements of 3.7 through 3.15.

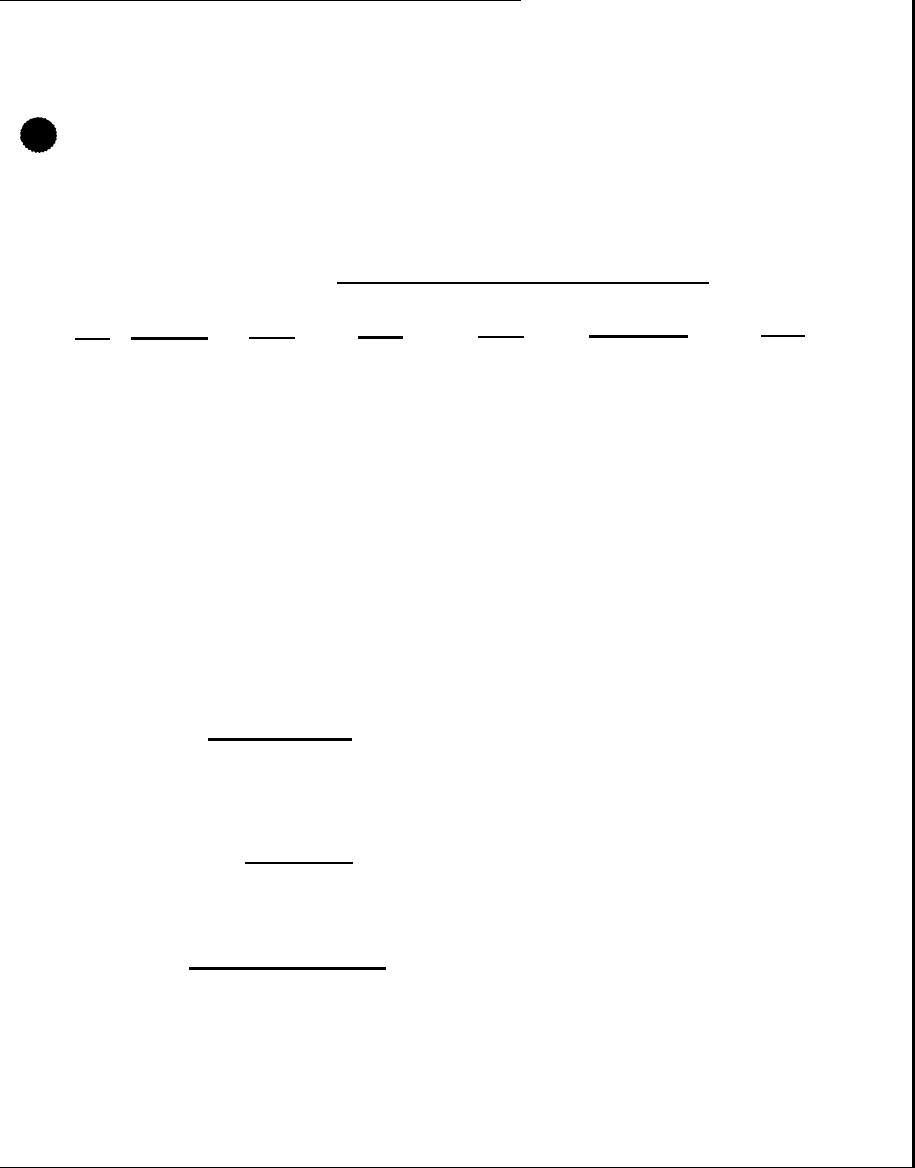

Storage and operating temperatures

TABLE III.

OPERATING

STORAGE

SOAK

SOAK

ROOM TEMP

TEMP

SOAK

SEQ

TEMP

0

4 hrs

+160O F

1

(+71 C)

0

2 hrs

+150 oF

2

(+6 5 c)

0

+60 F0 to +90F

4 hrs

3

0

(+16 c to 32 C)

O

0

-50 F

-50 F

4 hrs*

4 hrs

4

o

0

(-46 C)

(-46 C)

0

0

+60 F to +90 F

4 hrs

5

0

0

(+16 c to 32 c)

*Same 4 hrs as storage soak

S h o c k . This test is applicable to the First Article

4.12.2

Samples and the Reliability Assurance SamPles only. The quadrant

shall be positioned on Fixture 11747195 and secured to the shock

tester. The quadrant shall be subjected to a shock test in

accordance with 3.6.3. Upon completion of the shock, the quadrant

shall be examined and inspected to the requirements specified in

3.6.3.

Vibration "A". This test is applicable to the

4.12.3

Reliability Assurance Sample only. The quadrant shall be positioned

on Fixture 11747195 and secured to the vibration tester. The

quadrant shall be subjected to a vibration test in accordance with

3.6.4. Upon completion of the vibration test, the quadrant shall be

examined and inspected to the requirements of 3.6.4.

The quadrant shall be positioned on

4.12.4 Vibration "B".

Fixture 11747195 and vibrated i n a c c o r d a n c e w i t h t h e f r e q u e n c y a n d

-

duration as specified in 3.6.5. At the conclusion of the test, the

quadrant shall be subjected to a visual and tactile examination and

shall meet the requirements of 3.6.5.

The interchangeability gage 11747969

4.13 Interchangeability.

shall be applied to the mounting surface (keyway) of the quadrant to

assure maximum fit condition. The gage shall be firmly seated in

the keyway, without binding, and subsequently removed, to meet the

requirements of 3.15.

15

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |