|

|||

|

Page Title:

Table I. Classification of inspection. |

|

||

| ||||||||||

|

|  MIL-R-62197A(AT)

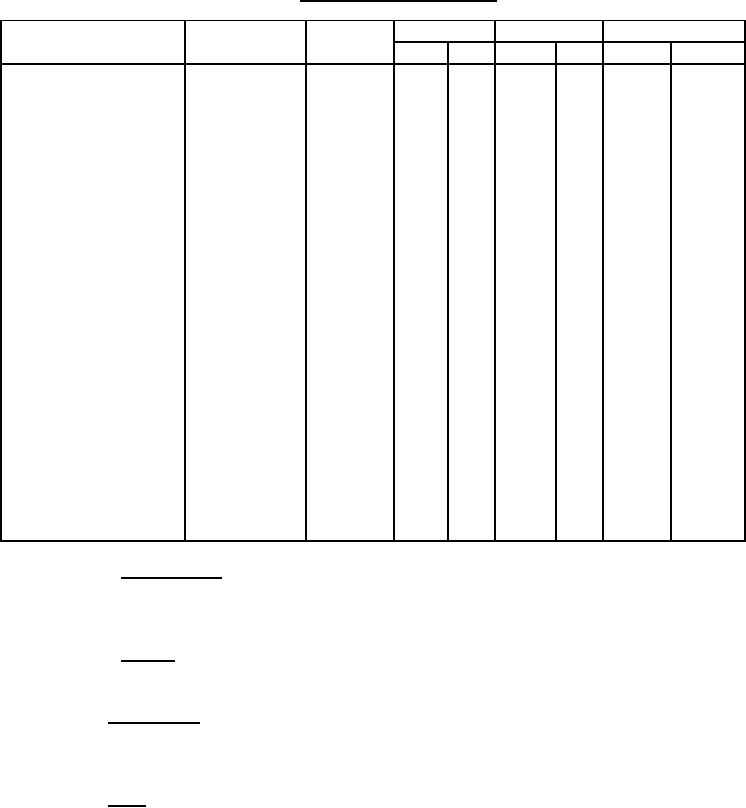

TABLE I. Classification of inspection.

First article

QCI

Control test

Title

Requirement

Test

PPI

IPI

Exam Test (1/50) (1/200)

Materials and

3.2 and 3.3

4.7.1

X

X

construction

Defects (see table III)

3.3 thru 3.3.5,

4.7.2

X

X

X

3.5 and 3.6

Insulation resistance

3.4.1

4.7.3

X

X

Dielectric strength

3.4.2

4.7.4

X

X

X

Contact characteristics

3.4.3

4.7.5

Rated load

3.4.3.1

4.7.5.1

X

X

X

Resistance

3.4.3.2

4.7.5.2

X

X

X

Life

3.4.3.3

4.7.5.3

X

X

X

Coil characteristics

3.4.4

4.7.6

Current

3.4.4.1

4.7.6.1

X

X

X

Voltage

3.4.4.2

4.7.6.2

X

X

DC resistance

3.4.5

4.7.7

X

X

X

Inductance

3.4.6

4.7.8

X

X

X

High temperature

3.4.7.1

4.7.9.1.1

X

X

X

Low temperature

3.4.7.1

4.7.9.1.2

X

X

X

Vibration

3.4.7.2

4.7.9.2

X

X

X

Shock

3.4.7.3

4.7.9.3

Basic design

3.4.7.3

4.7.9.3.1

X

X

X

High intensity

3.4.7.3

4.7.9.3.2

X

X

Humidity

3.4.7.4

4.7.9.4

X

X

X

4.5.1.1 Lot formation. An inspection lot shall consist of all relays of a single type, class,

style and part identification number (PIN), from an identifiable production period, from one

manufacturer, from one manufacturing location, submitted at the same time for acceptance.

4.5.1.2 Sample. The sample for QCI examination shall be randomly selected from the

inspection lot in accordance with table II.

4.5.2 Examination. The sample selected in accordance with 4.5.1.2 shall be examined

and defects classified as specified in table III (see 4.7.2). The acceptance number in all cases is

zero.

4.5.3 Tests. Each relay shall be subjected to the tests specified in table I.

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |