|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-10522K (PA)

in Table IV occur, if four (4) or more assemblies exhibit

any of the major A defects listed in Table IV, if six (6) or

more assemblies exhibit the major B defect, listed in Table

IV, if seven (7) or more assemblies exhibit a combination of

the major A and major B defects in Table IV, if eight (8) or

more assemblies exhibit the minor defect or a combination of

the major and minor defects listed in Table IV.

*4.4.3.6.2 After three (3) consecutive lots have complied

with the acceptance criteria of 4.4.3.6.1, fifty (50) assemblies

shall be selected from each lot for test. The lot shall be

rejected if, during the test, one (1) or more critical defects

as listed in Table IV occur, if two (2) or more assemblies

exhibit any of the major A defects in Table IV, if three (3)

or more assemblies exhibit the major B defect, if four (4)

or more assemblies exhibit the minor defect or a combination of

minor and major defects defects listed in Table IV.

4.4.3.7 Quick Leak Test. - Major B defect - Ten (10) cartons

in sealed barrier bags shall be selected from each lot for test.

If' two (2) or more packsges show evidence of air leakage during

testing or water leakage when package is opened, the lot shall be

rejected. The test shall be performed as specified in 4.5.7.

*4.4.4 Inspection Equipment. - The inspection equipment

required to perform the inspections and tests prescribed in

this specification is identified in the `paragraph Referance/

Inspection Method' column In the tables starting with para-

graph 4.4.2.1, and the test method paragraphs (see 4.5). The

contractor shall submit for approval, inspection equipment

designs In accordance with the terms of the contract. See

Section 6 of MIL-A-48078, and section 6.3 herein.

4.5 Test methods and procedures

4.5.1 Moisture content

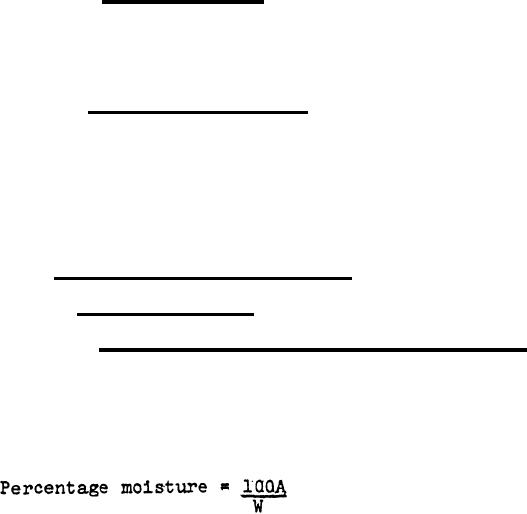

4.5.1.1 Moisture content of whistle composition. - An

accurately weighed portion of' approximately 5 gram of com-

position shall be transferred to a tared moisture dish. The

moisture dish and contents shall be placed in a drying oven

at 85 plus or minus 5 degrees C. for four (4) hours, cooled

In a desiccator and weighed. The percentage of moisture in

the sample shall be calculated as follows:

33

l

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |