|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-16059B(SHIPS)

be capable of sustaining the input static torques

heavier than 0.037 inch, as specified in table I, the

(rated torque) of table IV without permanent distor-

yarn shall not be heavier than 8 cut (800 yards per

tion or rupture in both directions of rotation.

pound). In all cases, the yarn shall be of a type

constructed on card machines.

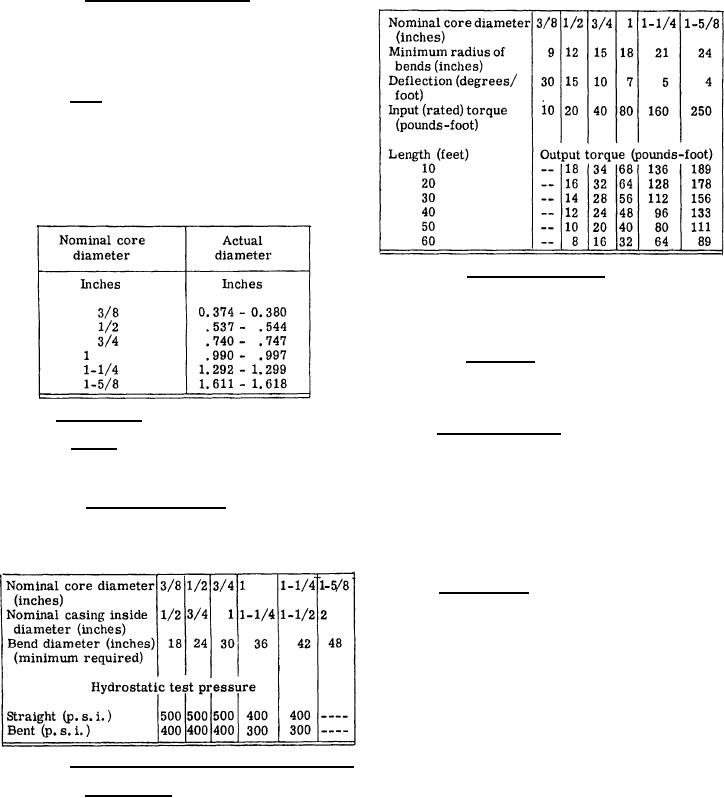

Table IV - Assembled flexible

3. 3.1.3 Galvanizing (zinc coated), - When the

shafting performance.

casing is galvanized (zinc coated) steel (see 3.3.1. 1),

the coating shall be smooth and tight, free from

pinholes, and of sufficient thickness to withstand

the corrosion test specified in 4.4.2.3. The coat-

ing shall not decrease the flexibility of the hose.

3.3.2 Core. - The flexible core shall consist of

several layers of helically wound, high strength,

steel wires, each layer wound in opposite direction

to the preceding layer. The number of wires in each

layer, the wire sizes and wire material may vary

between size of core and the manufacturer, The

core shall conform to table II.

Table II - Size of core.

3.4.2.2 Torque transmission. - Flexible shaft-

ing when mounted as in 4 .4.4 shall be capable of

transmitting the static torques of table IV for the

lengths indicated without permanent distortion or

rupture in both directions of rotation.

3.4.2.3 Deflection. - Flexible shafting when

mounted as in 4. 4.4 shall have a torsional deflec-

tion per foot of core length not greater than that

shown in table IV.

3.4 Performance.

3.5 Assembling details. -

3.4.1 Casing. - The casing shall be flexible,

3.5.1 Flexible shafting remote control systems

and properly constructed to prevent leakage, ex-

shall be designed, assembled, and installed in ac-

cessive wear, and breakage due to actual service,

cordance with Publication NAVSHIPS-250-648 -2.

3.4.1.1 Hydrostatic pressure. - The casing

3.5.2 The assembly of the core and terminal

shall withstand without leakage the hydrostatic

fittings shall be capable of withstanding 200 per-

test pressures of table III.

cent of the rated torque capacity of the core (see

table IV).

Table III - Casing performance.

3.6 Workmanship. - The workmanship shall be

first class in every respect.

4. QUALITY ASSURANCE PROVISIONS

4.1 The supplier is responsible for the perform-

ance of all inspection requirements as specified

herein, Except as otherwise specified, the supplier

may utilize his own or any other inspection facilities

and services acceptable to the Government. Inspec-

tion records of the examination and tests shall be

kept complete and available to the Government as

specified in the contract or order. The Government

3.4.2 Assembled flexible shafting performance. -

reserves the right to perform any of the inspections

3.4.2.1 Rated torque. - Flexible shafting, when

set forth in the specification where such inspections

assembled and mounted as indicated in 4.4.4 shall

2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |