|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-16059B(SHIPS)

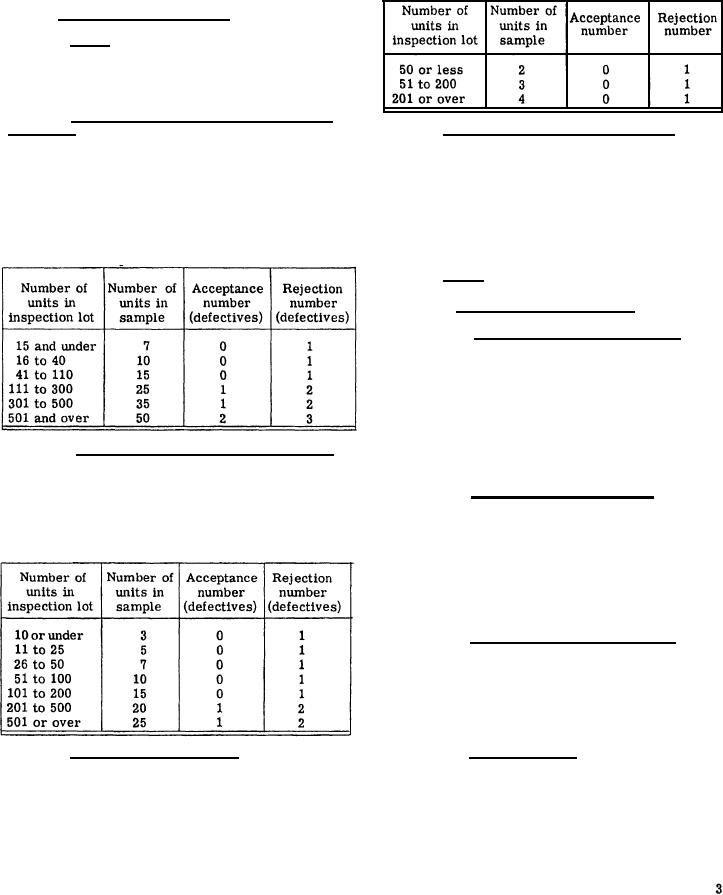

Table VII - Sampling for acceptance

are deemed necessary to assure supplies and serv-

lot torque test.

ices conform to prescribed requirements,

4.2 Lot acceptance inspection. -

4 . 2 . 1 L o t . - All mill lengths or assembled units

of shafting of the same core diameter presented un-

der one contract or order for delivery at one time

shall be considered a lot.

4.2.2 Sampling for visual and dimensional ex-

4.3 Visual and dimensional examination. - Each

amination, - A random sample of mill lengths or

of the sample units selected in accordance with table

assembled units shall be selected in accordance

V shall be visually and dimensionally examined to

with table V from each lot for visual and dimen-

verify compliance with this specification. Any unit

sional examination with lot acceptance based on

sampling inspection requirements in accordance

in the sample containing one or more visual or di-

mensional defects shall be rejected, and if the

with standard MIL-STD-105.

number of defective units in any sample exceeds the

acceptance number for that sample, the lot repre-

Table V - Sampling for visual and dimensional

sented by the sample shall be rejected.

inspection AQL (approx. ) = 1.5

percent defective.

4.4 Tests. -

4. 4.1 Inspection tests of the core. -

4. 4.1.1 Uniform condition of core wires. - All

cores selected for inspection shall be placed in a

position so that by the application of a slight twist

applied to one end, the core may be made to roll,

When it rolls, any spot along the core where the

wires have been overstressed, or where the wire

material has been hardened due to working or

nonuniform material, a wave will form at that

point (see figure 1); a section including this part

4.2.3 Sampling for tests (except torque test). -

of the core shall be removed before shipping.

A random sample of units shall be selected from

each inspection lot in accordance with table VI and

4.4. 1.2 Uniform winding of the core. - All

shall be subjected to the tests specified in 4.4.1

cores selected for inspection shall be placed in a

through 4. 4.2.3 inclusive.

position as indicated in 4.4. 1.1 Starting at one

Table VI - Sampling for lot acceptance tests

end, a loop shall be made to a minimum diameter

without straining the core and rolled the whole

(except torque test).

length of the core. At all points where the loop

diameter changes (see figure 2), the wires are not

wound uniformly and this section shall be removed

before shipping.

4,4.1.3 Core transverse flexibility test. - The

sample, selected in accordance with table VI, shall

be placed so that the end projects a distance equal

to the bend radius shown in table IV over an edge

so that the end drops free under its own weight.

The vertical drop shall not be greater than that

specified for the corresponding core size.

4.2.4 Sampling for torque tests. - A random

4.4.1.4 Assembled core. - All core fittings and

sample of units shall be selected from each inspec-

their attachment to the core shall be capable of with-

tion lot in accordance with table VII and shall be

standing 200 percent of the rated torque capacity

of the core (see table IV). The torque shall be ap-

subjected to the torque tests specified in 4.4.3 and

4.4.4.

plied while the core is held directly adjacent to

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |