|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-24686A(SH)

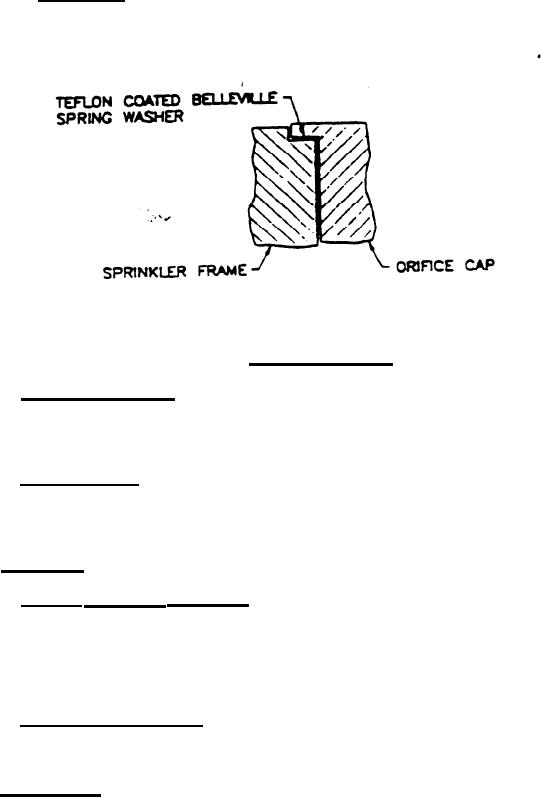

3.2.5.2 Washer seal . The seal shall be provided by a teflon coated

Belleville spring washer under the shoulder of the orifice cap, in the counterbore

in the sprinkler frame. The basic design concept is illustrated on figure 2.

Washer seal design.

FIGURE 2.

3.2.6 Prel oad retention. The automatic sprinkler shall be chemically or

mechanically staked to maintain the manufacturer's assembly load. The preload

shall not be alterable by the use of common hand tools without causing visible

damage to the sprinkler.

3.2.7 Special tools. Special tools shall not be required for installation

and routine maintenance of sprinklers. Special tools are defined as those tools

not listed in the Federal Supply Catalog (copies of this catalog may be consulted

in the office of the Defense Contract Management Area Operations (DCMAO).

3.3 Materials.

3.3.1 Materials of construction on . Materials of construction shall conform to

table III for each component. If a material is not specified for a particular

component, the material selected shall be suitable for the purpose intended.

Furthermore , material for internal components in contact with the system fluid

shall be compatible with seawater, and materials for external components shall be

compatible with a marine atmospheric environment.

3.3.2 Coats and platinings. Automatic sprinklers shall not be plated or

ing i

coated. Paint shall be permitted only for the purpose of color coding/marking in

accordance with 3.6.

3.4

Performance.

3.4.1 General Automatic sprinklers shall meet all of the performance

requirements for quick response automatic sprinklers specified in ANSI/UL 199. In

addition, automatic sprinklers shall meet all performance requirements for

standard automatic sprinklers specified in ANSI/UL 199.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |