|

|||

|

Page Title:

Table VII. Nominal orifice size and disc harge capacity |

|

||

| ||||||||||

|

|  MIL-S-24686A(SH)

Nominal orifice size and disc harge capac i ty .

TABLE II.

Nominal orifice

Discharge

Nominal

size marked

orifice

coefficient

Orifice

on frame

"K"

Pintle"

type

size (in.)

Yes

Yes

1.3 - 1.5

small

1/4

Yes

Yes

small

3/8

2.6 - 2.9

No

1/2

5.3 - 5.8

No

Standard

Yes

7.4 - 8.2

Yes

Large

17/32

*

A stationary pin or rod used to identify non-standard orifice sizes.

I

3.2.4 Inlet threads. The sprinkler body shall be constructed with a 1/2

inch NPT male thread in accordance with ANSI B1.20.1. Threads shall be clean cut

and true, and free from burrs, scoring, or chatter marks.

3.2.5 Seal desire. The seal between the orifice cap and the sprinkler body

shall conform to the design described in 3.2.5.1 or 3.2.5.2. No other seal

designs are acceptable.

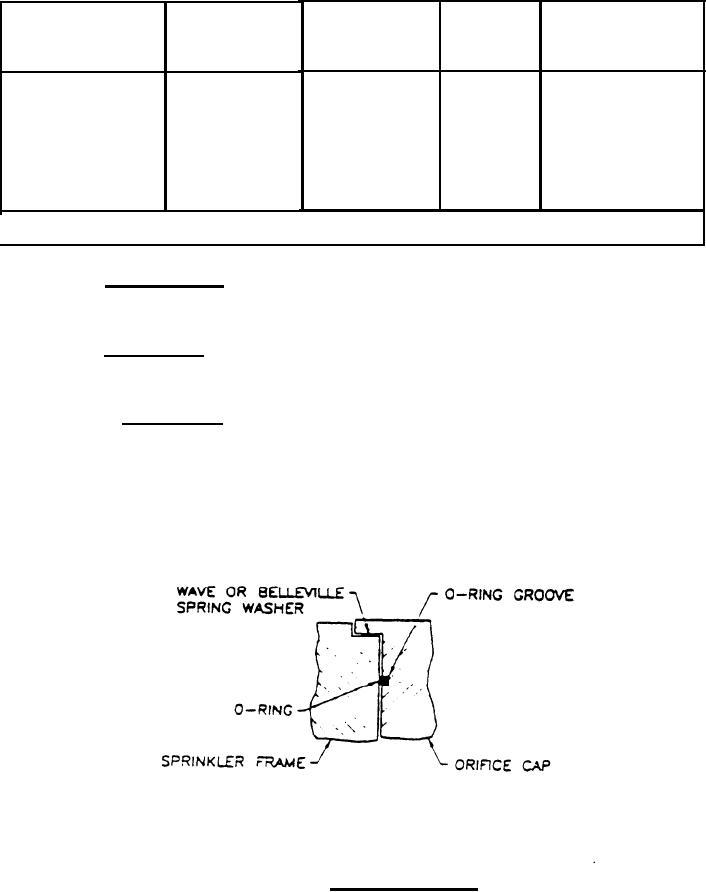

3.2.5.1 O-Ring seal. The seal shall be provided by a radial O-ring in the

orifice bore. The O-ring shall be captive in the O-ring groove in the orifice

cap . A wave spring, Belleville washer, or similar ejector or spring device shall

be under the shoulder area of the orifice cap, in the counterbore of the sprinkler

frame, as applicable. Any lubricant used on the O-ring shall be compatible with

the O-ring, orifice cap, and sprinkler body in a seawater environment. The basic

design concept is illustrated on figure 1.

O-Ring seal design .

FIGURE 1.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |