|

|||

|

|

|||

| ||||||||||

|

|  MIL-S-464F(ME)

3.5 Interchangeability. All parts having the same manufacturer's part number

shall be functionally and dimensionally interchangeable The drawing number

requirements of DOD-STD-100 shall govern changes in the manufacturer's part

number.

3.5.1 Common parts. Common hardware and fastening devices, such as bolts,

nuts, screws, and similar items, shall be held to a minimum number of types and

sizes and shall be threaded to the standards of FED-STD-H28.

3.6 Human factors engineering. The requirements described in MIL-STD-1472,

5.5 (labeling),5.7.7 (ladders), 5.4 (controls), 5.13.2 (safety labels and

placards), 5.13.5.4 (edge rounding), 5.13.6.2 (handrails, safety bars and

chains) shall be incorporated in the design of the spreader, as applicable The

spreader shall be designed such that 5th percentile female through 95th

percentile male soldiers (see MIL-STD-1472, 5.6 [anthropometry]) can operate and

maintain this item.

3.6.1 Design for maintainability. The spreader and its associated components

shall also be designed to incorporate MIL-STD-1472, 5.9 requirements, as

applicable.

3.7 Performance. The spreader shall perform as specified herein when

attached. The spreader shall uniformly distribute each type and size of material

specified in table I when traveling in both the forward and reverse directions,

The maximum spread width shall not be less than 8 feet. Block-off plates 1 foot

in length shall be provided to reduce the width of spread from 8 feet to 4 feet

in increments of 1 foot. No part of the spreader, (with the exception specified

in 3.8), including the truck hitch, shall interfere with the operation of the

dump truck body, including the tailgate.

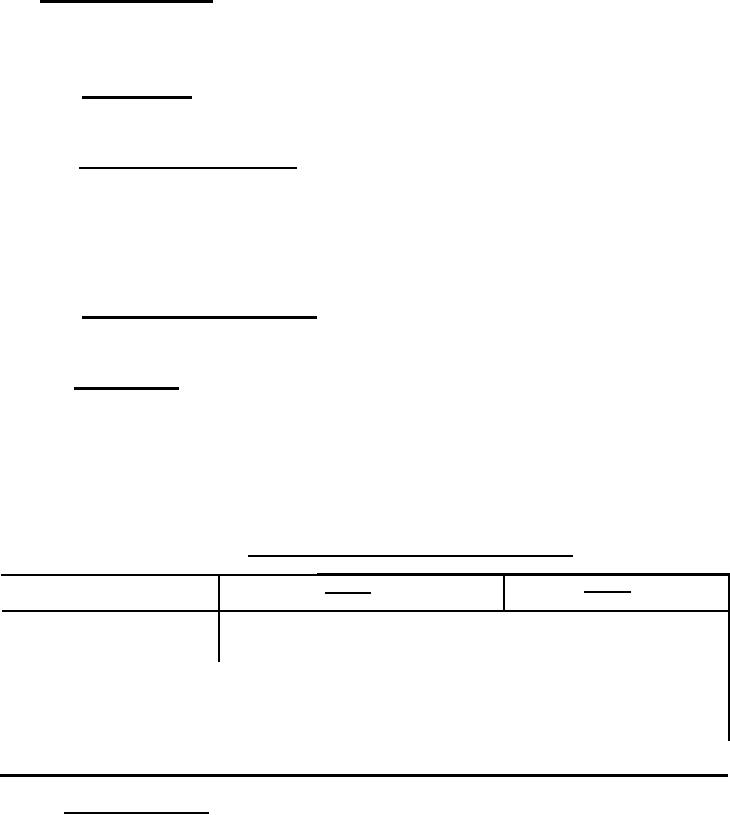

TABLE I. Percent passing each sieve by weight.

Col B

Col A

Sieve

Crushed Stone

Gravel or Crushed Stone

designation

100

1 inch

90-100

3/4 inch

100

20-55

1/2 inch

85-100

0-15

3/8 inch

10-30

0-5

No. 4

0-10

No. 8

0-5

No. 16

3.8 Receiving hopper. The hopper shall have a capacity of not less than 1

cubic yard and shall receive the material from the truck without loss or

spillage when the spreader is moving in forward and in reverse directions. The

hopper shall be constructed so that aggregate dumped into the hopper from the

dump truck will be fed by gravity to the feed roll and to the ground by the

revolving feed roll. During spreading operations with the truck body in a fully

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |