|

|||

|

Page Title:

Table I. Required tests for each grade of steel, |

|

||

| ||||||||||

|

|  MIL-S-81054A(OS)

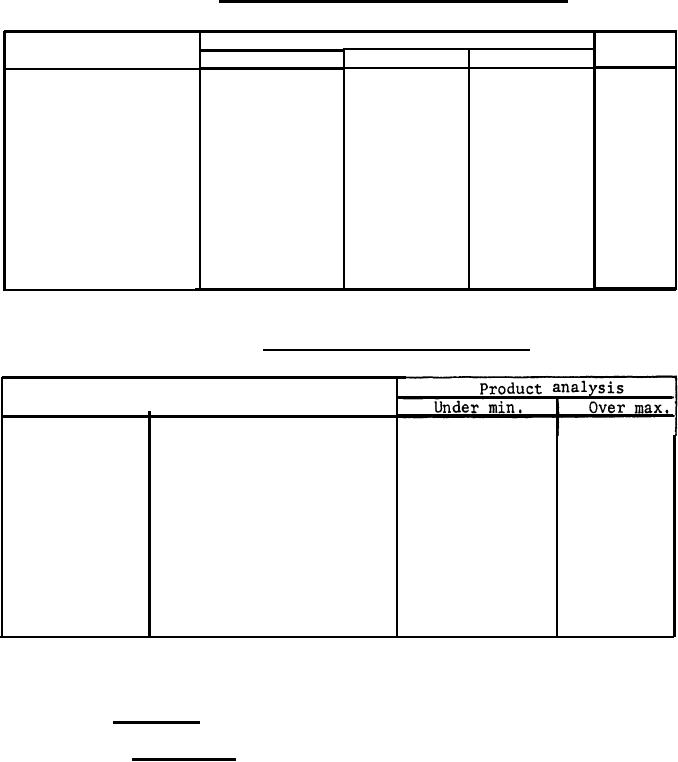

Required tests for each grade of steel,

TABLE I.

Forgings

Tests

Bars

Grade C

Grade B

Grade A

x

x

x

Chemical

x

Ultrasonic

x

x

x

x

Magnetic particle

x

x

x

Grain flow

x

Impact

x

x

x

x

Grain size

Decarburization

x

x

x

x

Inclusion rating

x

x

x

x

x

Hardenability

Tensile

x

x

x

x

Macroetch test

x

x

TABLE II.

Chemical composition of steel.

Element

Percent by weight

I

0.33 -

0,38

0,02

Carbon

0.02

Manganese

0,03

0,60 -

0.03

0,85

Silicon

0,05

0.40 -

0060

0.05

Chromium

0,03

0,65 -

0.90

0.03

Nickel

1,65 -

0,05

2,00

0.05

Molybdenum

0,02

0,30 -

0,40

0,02

Vanadium

0,02

0,17 -

0,23

0,02

l

0.010 Max.

(comp A)

Sulphur

0.005

0.025 Max.

(comp B) l

Phosphorous

0.025 Max.

(comp A)

06005

0,005

0,025 Max.

(comp B)

`Sulphur plus phosphorus shall be 0.025 percent maximum.

3.3.1,4 Condition.

* 3.3.1.4,1 Condition A. Condition A steel shall be annealed to a

maximum hardness of Rockwell 241 HB (100 HRB), in accordance with

ASTM E 9.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |