|

|||

|

Page Title:

Table III. Decarburization limits for bar stock, |

|

||

| ||||||||||

|

|  MIL-S-81054A(OS)

3.3.1.4.2 Condition B. Condition B steel shall be normalized and tem-

pered to a maximum hardness of 30 HRC (100 HRB).

3.3.1.5 Hardenability.

The steel shall be hardenable to a Rockwell

"C" hardness of 56 maximum at 1 inch and 47 maximum at 1-1/2 inches from

surface when tested in accordance with method ASTM A 225, using a normal-

izing temperature of 1700 10 F.

3.3.1.6 Grain size, The austenitic grain size shall be predominantly

No, 5 or finer with a single grain as large as No. 3 permissible per

ASTM E 112.

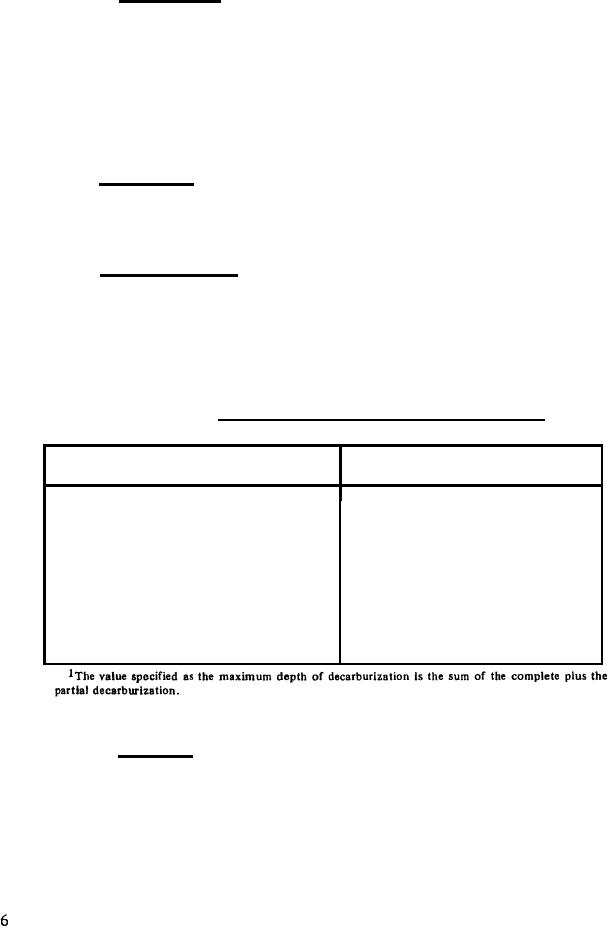

3.3.1.7 Decarburization.

3.3.1.7.1 Bars. Ground, turned, or polished bars shall be free from

decarburization ground, turned, or polished surfaces. Hot-rolled

bars shall have decarburization no greater than that specified in

table 111.

TABLE 111.

Decarburization limits for bar stock,

Nominal distance between

Maximum depth of

1

opposite faces (inch)

decarburization (inch)

up to 0.375

0.010

0.375 to 0.500

0.012

0.500 to 0.625

0.014

0.625 to 1.000

0.017

1.00 to 1.50

0.020

1.50 to 2.00

0.025

2.00 to 2.50

0.030

2.5O to 3.00

0.035

0.045

over 3.00 to 4.0 inclusive

3.3.1.7.2 Forgings. Forgings, all grades, shall have a decarburization

of 0.035 inch depth, maximum, This limit shall include partial and com-

plete decarburization.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |