|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-50009A

tatively to a 250-ml separator funnel and

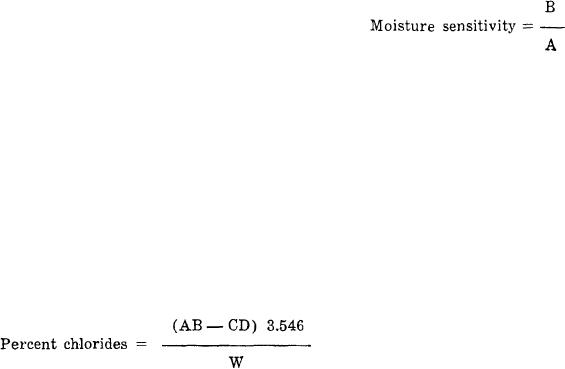

sensitivity as follows:

draw off the aqueous bottom layer into a

glass-stoppered, 500-ml Erlenmeyer flask.

Wash the oil layer three times with 25 ml

portions of water, drawing off the aqueous

layer after each washing into the 500-ml

4.5.7 Apparent density. Determine the ap-

flask containing the first draw-off. To this

parent density in accordance with ASTM

flask add 5 ml of nitrobenzene, 5 ml of ferric

method D1 18254 and report the results in

ammonium sulfate indicator, and 2 ml of

g per ml.

0.02 N potassium thiocyanate. Titrate with

0.02 N silver nitrate until the indicator color

4.6 Acceptance /rejection criteria. If the

disappears and then add 5 ml excess of silver individual or composite specimen fails to

nitrate. Shake vigorously for approximately

meet the test requirements of the specifica-

5 minutes to assure complete coagulation of tion, the lot represented shall be rejected.

the silver chloride, and then back titrate

with 0.02 N potassium thiocyanate. Run a

5. PREPARATION FOR DELIVERY

blank and apply any significant corrections.

Calculate the percent chloride as follows:

5.1 Packaging.

5.1.1 Level A.

5.1.1.1 Two-pound quantity. Two pounds

w h e r e : A = milliliters of silver nitrate,

1 ounce of thickener shall be packaged in

total.

a type II hermetically sealed rectangular

can, conforming to Specification MIL-G

B = normality of silver nitrate,

10464. The can interior surfaces shall be

c=

milliliters of potassium thiocy -

coated with a l-roil thick clear phenolic or

anate.

vinyl coating. The exterior can surfaces shall

D = normality of the potassium

be coated as specified in the can specification

thiocyanate.

with color of the finish coat conforming to

color No. 34087 of Federal Standard No, 595.

W = weight of specimen in g.

4.5.6 Moisture sensitivity. Prepare and

5.1.1.2 Thirty-three and one-third pounds.

test a 2 percent gel as specified in 4.5.2.1

Thirty-three and one-third pounds 4

except that a single gel shall be prepared

ounces of thickener shall be packaged in a

from the specimen. Designate the consistency

bag conforming to type III, class 6, style B,

of this specimen as A. Take a second portion

bag number P55, of Specification PPP-B-

of approximately 75 g from the specimen

35. The bag shall have approximate dimen-

and spread it evenly over the surface on an

sions of 12 by 4 by 36 inches. After filling,

aluminum tray having an area of approxi-

closure shall be accomplished in accordance

mately 120 square inches. Place the tray in

with the appendix of the bag specification.

a humidity cabinet maintained at 8001?. and

The polyethylene bag liner shall be closed by

80-percent relative humidity for a period

heat seal.

of 15 minutes 30 seconds. Transfer the

5.2 Packing.

humidified material to a container, leaving

not more than 10 percent void, and tightly

5.2.1 Level A.

close. Prepare and test a 2-percent gel as

specified in 4.5.2.1. Designate the consistency

5.2.1.1 Two-pound quantity. Twelve cans

of this specimen as B. Calculate the moisture

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |