|

|||

|

|

|||

| ||||||||||

|

|  MILT8504B

4.3 Quality conformance inspection. Quality conformance inspection shall consist of

sampling plans A through J specified herein. Samples shall be labeled completely with

information identifying the purpose of the sample, name of product, specification

number, lot number, date of sampling and contract number.

4.3.1 Inspection

4.3.1.1 Inspection lot. A lot shall consist of one size and wall thickness from one heat of

steel, and annealed in the same charge (batch anneal) or all tubing of the same size

and heat annealed at the same temperature, time and atmosphere, without interruption,

in a continuous furnace.

4.3.2 Surface condition

4.3.2.1 Conditioning of surface. A 1foot section shall be selected from each lot of

tubing and split lengthwise. Onehalf shall be immersed in an aqueous solution of 15

percent nitric acid and 3 percent hydrofluoric acid by volume at 100F to 120F for 15

minutes. After immersion, the specimen shall be washed and dried. The two halves

shall then be compared as to the appearance of inner and outer surfaces. Difference in

color and appearance, other than minor changes in shade and texture, shall be cause

for rejection.

4.3.2.2 Loose material. Wads of firmly compacted clean white cloth or fibrous material

shall be forced through the bore of each of two sample tubes selected from each lot,

and any soiled areas examined at 10 x magnification for the presence of grit, metallic

flakes, or other detrimental materials. The presence of such particles shall be cause for

rejection.

4.3.2.3 Surface roughness. A 1foot section shall be selected from each lot of tubing

and split lengthwise. The inner and outer surfaces of both halves shall be examined for

surface waviness and lay in accordance with ANSI B 46.1. The failure of any tubing to

meet the requirements of 3.5.1 shall be cause for rejection.

4.3.2.4 Examination of samples. Samples selected in accordance with table V shall be

examined for conformance to dimensions and tolerances (3.7), weld bead (3.8),

straightness (3.9), length (3.10) identification marking (3.11), workmanship

requirements (3.12) and preparation for delivery (section 5).

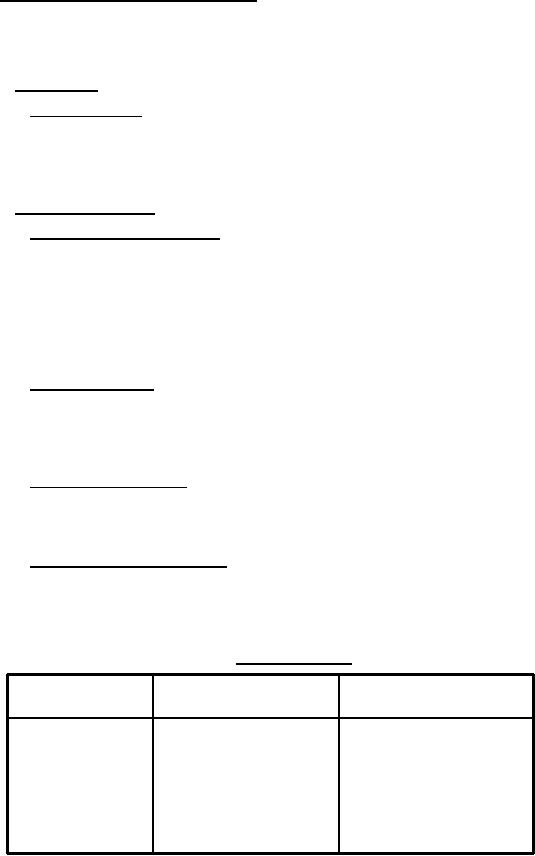

TABLE V. Sampling plan

Lot size

Sample size

Acceptance No.

1 to 110

5

0

111 to 500

7

0

501 to 800

10

0

801 to 1200

15

0

Over 1200

25

0

7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |