|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-46727C(AT)

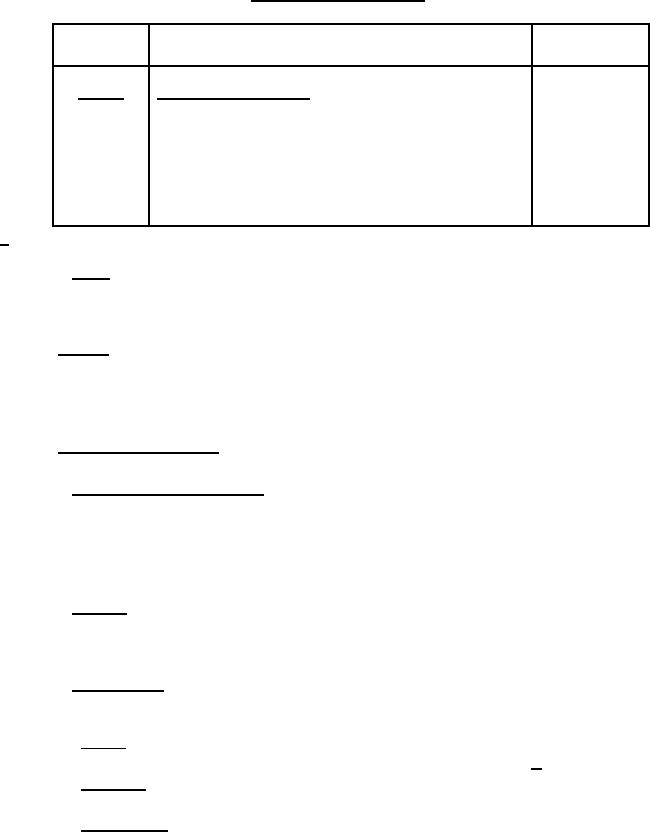

TABLE. Classification of defects Continued.

Method of

Category

Defect

examination

Minor

AQL 2.5% Defective

SIE or

201

Dimensions not affecting interchangeability not

Functional

within tolerance (see 3.3).

SIE

Weight greater than specified (see 3.3.5).

202

Visual

Marking illegible or incorrect (see 3.5).

203

Visual

Finish not as specified (see 3.6).

204

Visual

Faulty workmanship (see 3.7)

205

1/ SIE = Standard Inspection Equipment.

4.5.3 Tests. Each valve selected in accordance with 4.5.1.3 shall be subjected to the quality

conformance tests specified in table I, in the order specified using an AQL of 1.0 on the basis of

percent defective.

4.6 Failure. Failure of any valve to pass any of the specified quality conformance tests shall

be cause for the Government to refuse acceptance of the production quantity represented, until

action taken by the contractor to correct defects and prevent recurrence has been approved by the

Government.

4.7 Methods of inspection.

4.7.1 Materials and construction. Conformance to 3.2 through 3.3.4 shall be determined by

inspection of contractor records providing proof or certification that design, construction,

processing, and materials conform to requirements. Applicable records shall include drawings,

specifications, design data, receiving inspection records, processing and quality control

standards, vendor catalogs and certifications, industry standards, test reports, and rating data.

4.7.2 Defects. Conformance to 3.3, 3.3.3 through 3.3.5 and 3.5 through 3.7, shall be

determined by examination for the defects listed in table II. Examination shall be visual, tactile,

or by measurement with standard inspection equipment.

4.7.3 Performance. Unless otherwise specified (see 6.2), performance testing shall be

conducted under the following conditions:

a. Fluids. All tests shall be performed with hydraulic fluid conforming to MIL-H-5606

or MIL-H-6083. The hydraulic fluid temperature shall be 90 + 20F.

b. Cleaning. All grease or foreign material shall be removed from interior parts of the

valve before testing.

c. Air removal. Air shall be completely removed from all hydraulic portions of the

valves prior to tests.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |