|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-5525C

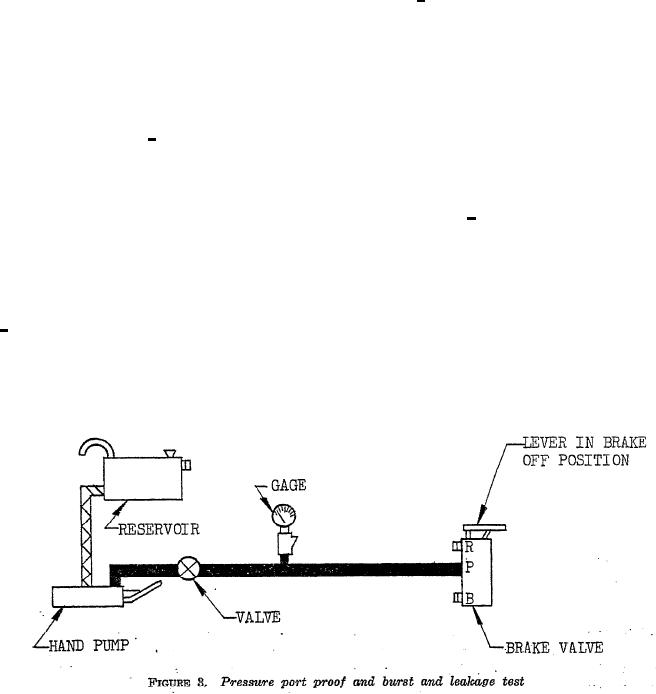

4.7.7.1 Pressure decrease. A typical test set-

4.7.5.2 With the valve in full brake-on posi-

up for compensation of pressure decrease is

tion, leakage shall be measured at the return

shown on figure 1. Pressure shall be maintain-

port when outlet pressure at the brake port

ed in the brake line at approximately 75 per-

is maximum and 3,000 psi is held at the inlet

cent of the operating range under a system

port.

pressure of 3,000 psi. The bleeder valve shall

4.7.6 Endurance. System operating pressure

then be opened to permit a flow of 2 cubic

shall be applied at the pressure port, and the

inches per minute to permit the pressure in

brake valve shall deliver fluid at the rated

the brake line to drop. The pressure in the

output pressure throughout 10,000 full stroke

brake line shall not fall below 85 percent of

cycles and 90,000 cycles at a load pressure

the original brake pressure before compensa-

corresponding to 60 percent of full load. A

tion is effected. The compensated pressure shall

typical setup for this test is indicated in fig-

be within + 15 percent of the original brake-

ure 4. The output pressure shall be checked at

line pressure.

least once every 10,000 cycles. No components

of the valve assembly shall be replaced during

4.7.7.2 Pressure increase. A typical test set-

this test except packings which may be re-

up for compensation of pressure increase is

placed after 50,000 cycles. No malfunctioning

shown on figure 1 and the testing procedure

shall occur. At the completion of this test, the

shall be the same as for pressure compensation

full stroke brake pressure shall not have

during pressure decrease, except that an at-

changed in excess of + 5 percent, and the in-

tempt shall be made to increase the pressure

ternal leakage shall not exceed that permitted

at the brake port to approximately 115 per-

by the detail specification or drawing. The

cent of the original brake pressure by means

external leakage through sliding seals shall

of the hand pump. The compensated pressure

not. exceed a rate of 1 drop per 50 cycles of

shall be within + 15 percent of the original

operation.

brake-line pressure.

4.7.7 Pressure compensation. The brake

4.7.8 Extreme temperature operation. These

valve shall compensate for pressure changes

tests shall be conducted on the preproduction

at the brake port. At any brake pressure set-

test sample valves having minimum clearance.

ting, the compensating range shall not. exceed

These valves shall operate at any temperature

+ 5 percent, or as specified in the detail speci-

o

from --54 to +71 C (--65 to + 160 F)

fication or drawing, of the maximum brake

without sticking, binding, or other malfunc-

pressure initially attained at this setting.

6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |