|

|||

|

Page Title:

Temperature and humidity, non-operating condition |

|

||

| ||||||||||

|

|  MIL-V-82443(OS)

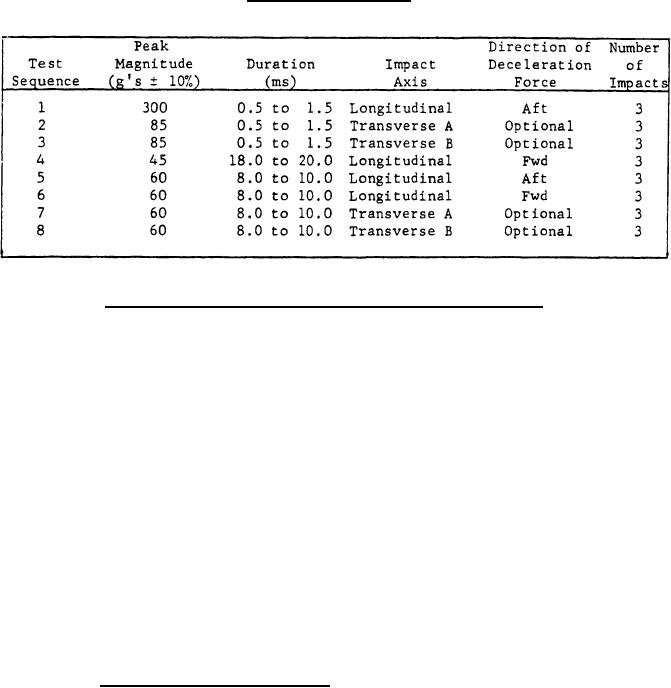

TABLE VIII

SHOCK TEST SCHEDULE

4.4.4.7

Temperature and humidity, non-operating condition. Four

preproduction valves shall be subjected, in the non-operating condition,

to temperature and humidity cycling in the following manner: The specimen

shall be placed in a temperature chamber which has been stabilized at an

environmental temperature of -45 F +0 -5 F. The specimen shall

remain in the environment for 6 hours. (As an alternative procedure, the

specimen may be placed in the chamber, with the chamber at roomamvient

temperature. Chamber temperature shall then be reduced to -45 F +0 -5 F

within 2 hours maximum. The specimen shall thereafter remain in the chamber

for 4 hours). The specimen shall then be subjected to an environmental

temperature of +140 F +5 F -0 F. Maximum transition time from the

low temperature to the high temperature shall be 2 hours. The specimen

shall remain in the high temperature environment for 4 hours. This

cycle shall be performed 3 times: maximum transition time shall be 2

hours. The specimen shall subsequently be subjected to an environment of

+110 F +5 -0 F at a minimum relative humidity of 95 percent for a

minimum of 8 hours. Thereafter, 2 valves shall be operated in accordance

with 4.4.4.8 and 2 valves shall be operated in accordance with 4.4.4.9.

Prior to operation the valves may be wiped dry. Drying by an air blast

or oven is not permitted.

4.4.4.8

Low temperature operating. Before testing, the valve,

installed in its test chamber in the ready condition, shall be conditioned

at a temperature of 0 F * 5 F for a period of 1 hour. The valve shall

then be operated in accordance with and meet the requirements of

4.4.4.13 at an environmental temperature of +32 F 5 F. The valve

shall thereafter meet the requirements of 4.4.4,14 through 4.4.4.17.

13

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |