|

|||

|

Page Title:

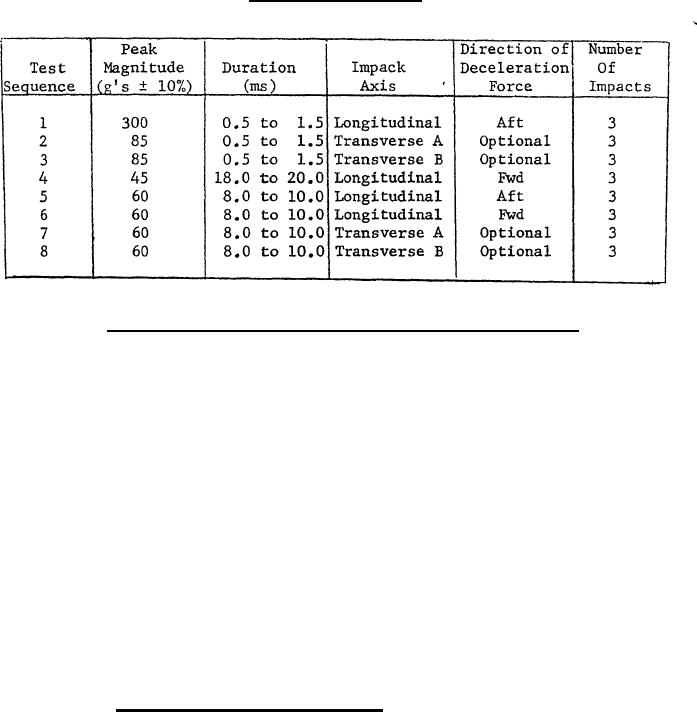

Table VIII. Shock Test Schedule |

|

||

| ||||||||||

|

|  MIL-V-82444A(OS)

TABLE VIII

SHOCK TEST SCHEDULE

4.4.4.7 Temperature and humidity, nonoperating condition. Four

preproduction valves shall be subjected, in the nonoperating condition,

to temperature and humidity cycling in the following manner: The

specimen shall be placed in a temperature chamber which has0 been stab-

ilized at an environmental temperature of -45 F +0 -5 F. The specimen

shall remain in the environment for 6 hours. (As an alternative procedure,

the specimen may be placed in the chamber, with the chamber at room ambient

0

0

0

temperature. Chamber temperature shall then be reduced to -45 F +0 -5 F

within 2 hours maximum. The specimen shall therafter remain in the chamb

for 4 hours). The specimen shall then be subjected to an environmental

temperature of +140 F +5 F -0 F. Maximum transition time from the

low temperature to the high temperature shall be 2 hours. The specimen

shall remain in the high temperature environment for 4 hours. This cycle

shall be performed 3 times; maximum transition time shall be 2 hours. The

specimen shall subsequently be subjected to an environment of +110 F

0

0

+5 -0 F at a minimum relative humidity of 95 percent for a minimum of 8

hours. Thereafter, 2 valves shall be operated in accordance with 4.4.4.8

and 2 valves shall be operated in accordance with 4.4.4.9. Prior to

operation the valves may be wiped dry. Drying by an air blast or oven is

not permitted.

*

4.4.4.8 Low temperature operating. Before testing, the valves

installed in its test chamber in the ready condition, shall be condit-

0

ioned at a temperature of 0 F 5 F for a period of 1 hour. The valve

shall then be operated in accordance with and meet the requirements of

4.4.4.11 at an environmental temperature of +32 F 5 F. The valve shall

thereafter meet the requirements of 4.4.4.12 through 4.4.4.14.

12

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |