|

|||

|

Page Title:

Resin and additives, kraft and polyester staple fiber |

|

||

| ||||||||||

|

|  MIL-C-48868E (AR)

4.5.1.3.5 Resin and additives, kraft and polyester staple

fiber. Calculate the percent resin and additives, kraft and

polyester staple fiber as follows:

% Resin + % additives + % kraft + % polyester staple fiber

= 100 - (% NC + % Acrylic + % DPA)

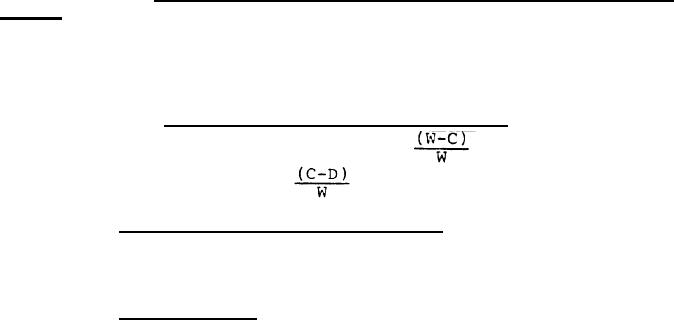

4.5.1.3.6 Methylene chloride extractable. Calculate the

total methylene chloride extractable

x 100 and the

total acetone extractable

x 100

4.5.2 Stability heat test (134.5C). Samples shall be

tested in accordance with MIL-STD-286, Method 404.1.2, heat

tests at 134.5C. Test is considered destructive and-samples

should be removed from lot.

4.5.3 Residue test. The test shall be performed at a

Government Proving Ground. Empty containers will be loaded

with M10 propellant and sealed in accordance with dwg. 9312698.

Loaded containers shall then be assembled to inertfilled M720

cartridges in accordance with the appropriate zones as listed

in 4.5.3.1 and 4.5.3.2. Test rounds shall be conditioned for a

minimum of eight hours at 70F plus or minus 5F and fired

within two minutes after removal from conditioning environment.

Rounds shall be fired at night from a M224 mortar (standard or

ballistic tube) at a firing elevation of 800 roils, at a uniform

rate of twelve to fifteen rounds per minute. The time of

descent for the round from muzzle to base shall not be more

than two seconds. The tube shall be dry swabbed and the

elevation checked between the firing of each group.

Observation shall be made for hangups (see 6.8), secondary

flame, and flaming debris. The lot shall be accepted if no

hangups occur, no rounds exhibit secondary flame at any zone,

and no flaming debris reach the ground at zone 4 only.

If a hangup occurs, the test round shall be removed from

the tube and an examination shall be conducted of the tube and

test round to determine if the hangup was caused by residue.

If the hangup was not caused by residue, the test shall be

continued.

If the hangup was caused by residue, firing of test

rounds shall be discontinued. The tube shall be dry swabbed

and a group of reference rounds shall be immediately fired.

32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |