|

|||

|

|

|||

| ||||||||||

|

|  MIL-F-20627B

The workmanship shall be

3.7 Workmanship.

3.3.2.2 Filtering ability. - The filter elements

such as to produce filter assemblies and filter ele-

shall be tested in accordance with 4.5.4. The dirt

ments in accordance with the design and operating

storage capacity of one class 2 or two class 1 cle-

characteristics specified herein and in accordance

ment(s) shall be not less than 200 grams. The pres-

with the practices used in the manufacturing of

sure drop shall not exceed 15 pounds per square

similar items of good commerical quality.

inch (p.s.i.) during the test. The average solids

content of the effluent samples taken during the ad-

4 QUALITY ASSURANCE PROVISIONS

dition of the 200 grams of solid contaminant shall

not exceed 10 milligrams per liter when analyzed in

4.1 Responsibility for inspection. - Unless

accordance with 4.5.4.4.2. Analysis of the samples

otherwise specified in the contract or purchase

for water content is not required.

order, the supplier is responsible for the perform-

ance of all inspection requirements as specified

3.3.3 Differential pressure (element). - The

herein. Except as otherwise specified, the sup-

filter element shall show no evidence of deformation

plier may utilize his own facilities or any com-

or damage when tested in accordance with 4.5.5.

mercial laboratory acceptable to the Government.

The Government reserves the right to perform any

3.3.4 Shock .- Filter assemblies of type I,

of the Impactions set forth in the specification

class 1 and 2 and type II, class 1 and 2 shall be

where such inspections are deemed necessary

shock tested in accordance with 4.5.7. After being

to assure supplies and services conform to pre-

subjected to the shock test the assembly and ele-

scribed requirements

ment(s) shall meet the requirements of MIL-S-901.

Performance after shock shall be defined as meet-

4.2 Materials and equipment required for tests. -

ing the requirement of 3.3.2 for the flow rate and

Materials and equipment required to conduct the

filter ability and 3.3.5 for pressure test. Accept-

tests specified herein shall be as follows:

ability of filter assembly and element shall be

determined separately. Failure of one will not

(a) Standard filter or filter element. - A

necessarily be cause for rejection of the other.

standard filter or a standard filter ele-

ment required shall be in accordance

3.3.5 Pressure (case) (type I). - The filter as-

with the applicable provisions specified

sembly for the type I, filters shall be capable, when

herein.

tested-as specified in 4.5.6, of withstanding a pres-

(b) Reference test oils. - Test oils required

sure of not less than 150 p.s.i. without showing any

in the test methods shall conform to the

evidence of leakage, permanent deformation or other

following:

damage. The class 3 and 4 filter assemblies shall

(1) Marine Diesel fuel oil in accord-

withstand a pressure of 100 p.s.i.

ance with MIL-F-16884.

(2) Viscous oil .- Any type of viscous

3.4 Product identification. - All filter assemblies

oil or lubricant may be used for

and filter elements shall be plainly marked in ac-

the differential pressure test

cordance with MIL-STD-130. Marking shall include

specified in 4.5.5. A No. 6

the following information:

boiler fuel has been found satis-

factory.

Filter assembly, filter element (whichever is

(c) Contaminant .- Solids contaminant shall

applicable), fluid, pressure; for engines with

be standardized air cleaner test dust,

liquid fuel injection systems.

fine grade, package No. 1543094 (this

Class.

material may be obtained from AC

Federal stock No.

Spark Plug Division, General Motors

Manufacturer's name or trademark.

Corporation, Flint, Michigan), having

3.5 Interchangeability. - All parts having the

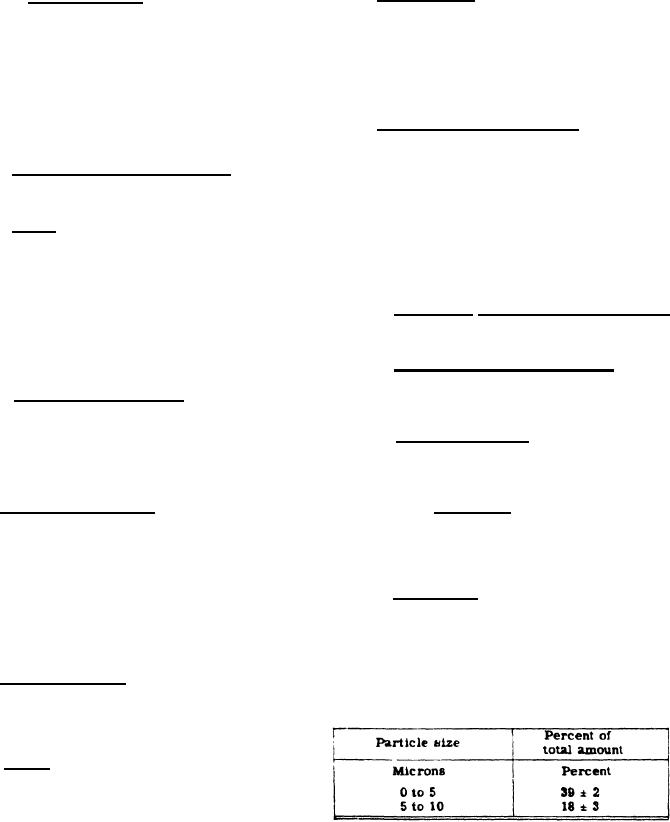

an approximate particle size distrtibution

same manufacturer's part number shall be function-

as shown in table I.

ally and dimensionally interchangeable. The draw-

Table I - Particle size distribution

ing number requirements of MIL-D-70327 shall

govern changes in the manufacturer's part number.

3.6 P a r t s . - Parts not specified herein shall be

selected in accordance with MIL-STD-143.

3

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |