|

|||

|

|

|||

| ||||||||||

|

|  MIL-H-904J

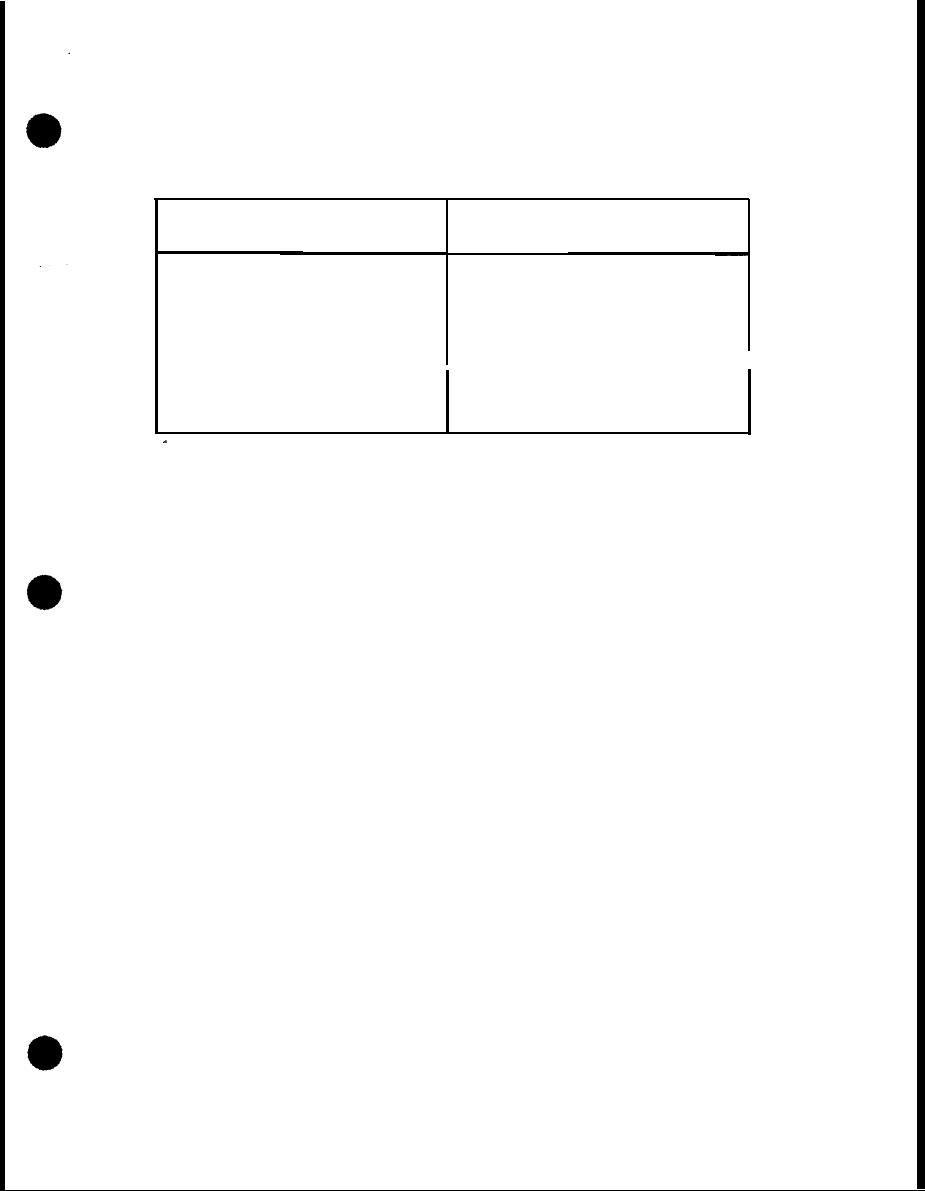

TABLE L Hook throat openings.

Hook with safety device,

1

Hoist rated load, tons

throat opening, inches

(min)

(min)

1/4 - 3/4

3/4

1

29/32

l-1/2

1

2-3

1-1/8

4

1-3/8

5-6

1-5/8

7-12

2-1/16

12-1/2 -14

2-1/4

15-19

2-3/4

20

3

1

2,000 pounds per ton.

33.6 Hoist brake. Hoist construction shall provide for automatic brake operation to secure

a suspended load if the hand chain is released or operating mechanism fails. Lowering shall be

possible only by manual operation of the hoist (hand chain or hand lever). The brake device shall

be self-adjusting for the service life of the brake lining. The brake shall support the required hoist

loads with no evidence of permanent deformation or excessive wear (see 4.7 and 4.7.8.3). The

brake device and brake surfaces shall be protected against the retention of dirt, dust, and water.

33.7 Trolleys (plain and geared).

Trolley requirements shall be as specified in 3.3.7.1

through 3.3.7.7.

3.3.7.1 Wheels. Trolleys shall be provided with at least four steel wheels. Trolleys up to and

including 3-ton capacity shall have wheels of steel with treads hardened to a minimum depth of

0.020 inch. For trolleys over 3-ton capacity, wheels shall be forged or solid steel with treads

hardened to a minimum depth of 0.063 inch. Trolley wheels shall have treads hardened to

minimum 285 Brinell hardness number. Wheels shall be concentric within 0.030 inch, and cast

wheels shall be machined, if necessary, to maintain a concentricity of 0.030 inch. Where the wheel

mounting arrangement is such that the wheels are not canted to the flange of "X" beam (S-section)

trolley track (tapered treads), wheel treads shall be a convex shape to minimize wear. The

operating device for geared trolleys shall be a chain wheel equipped with an endless chain of a

length as specified in 3.3.22. Unless otherwise specified (see 6.2), trolley wheel spacing shall be

for use on applicable standard "I" beam flange size.

33.7.1.1 Wheel axles. Wheel axles shall be made of carbon or alloy steel.

3.3.7.2 Wheel bearings. The trolley wheels shall be equipped with anti-friction bearings. The

wheel bearings shall be protected to exclude foreign matter.

9

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |