|

|||

|

Page Title:

Table VI. End item dimensional examination criteria |

|

||

| ||||||||||

|

|  MIL-L-43693A(GL)

TABLE V. End item visual defects for rope (cont'd)

Classification

Examine

Defect

Major Minor

102

Fiber other than specified

Rope (cont'd)

Any braider yam splices

201

202

Loose fiber ends on surface

Ends not taped and seared as

203

Specified

Dirt, grease, oil, or other

Workmanship

204

foreign matter

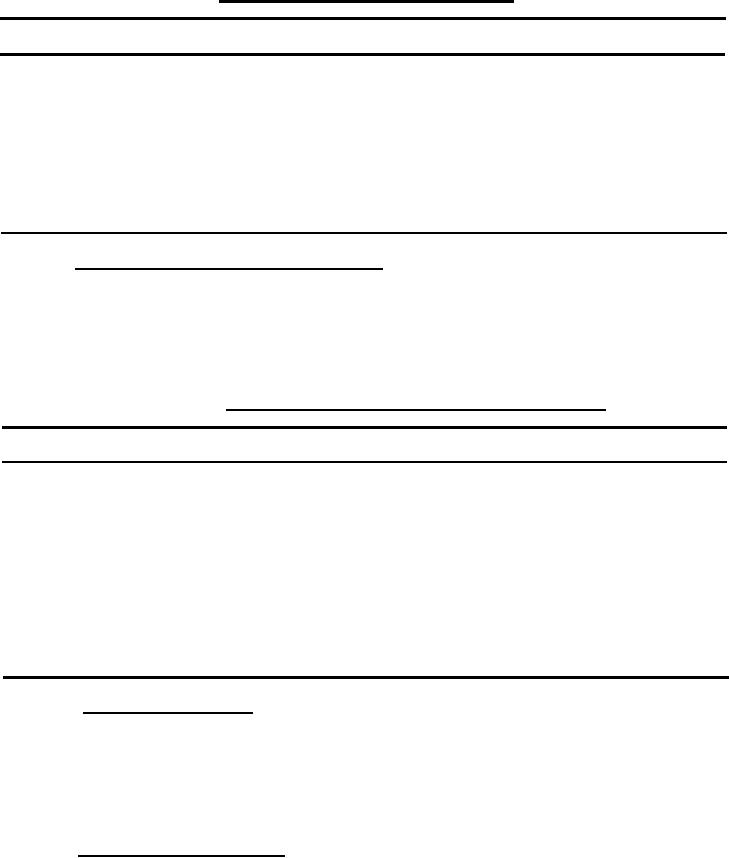

4.4.4 End item dimensional examination. The end items shall be examined for

conformance to dimensions on the drawings specified in section 2. Only those

dimension that can evaluated without damging or disassembling the end items

shall be examined. Any dimensitons not within the specified tolerance shall be

considered a defect. The lot size, sample unit, inspection level, and AQL,

expressed in terms of defects per hundred units, shall be as specified in

table VI.

TABLE VI. End item dimensional examination criteria

Lot size expresded

Inspection

Component

level

AQL

in units of

Sample unit

Harness assemblies

Harness assembly

S-3

6.5

1 Harness assembly

Carrying case

Carrying cases

6.5

S-3

1 Carrying case

Governor assembly

Governot assemblies

6.5

S-3

Governor assembly

and governor

and governor

and governor

wear gages

Wear gage

wear gage

Rope

Ropes

S-3

6.5

1 Rope

4.4.5 End item testing. One complete snap hook assembly or ring harness

or governor shall be tested as specified in the applicable drawings (see 3.2.2)

for conformance to the proof loadrequirements contained therein. The lot size

shall consist of completely fabricaticated rope snap hook assemblies, ring

harnesses, or governors offered for inspection at one time. The sample size

Shall be the number of end items indicted by inspection level III. Any test

failure shall be cause for rejection of the lot.

4.4.6 Packaging examination. The fully packaged end items shall be examined

for the defects listed below. The lot size shall be expressed in units of

11

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |