|

|||

|

|

|||

| ||||||||||

|

|  MIL-M-20439A

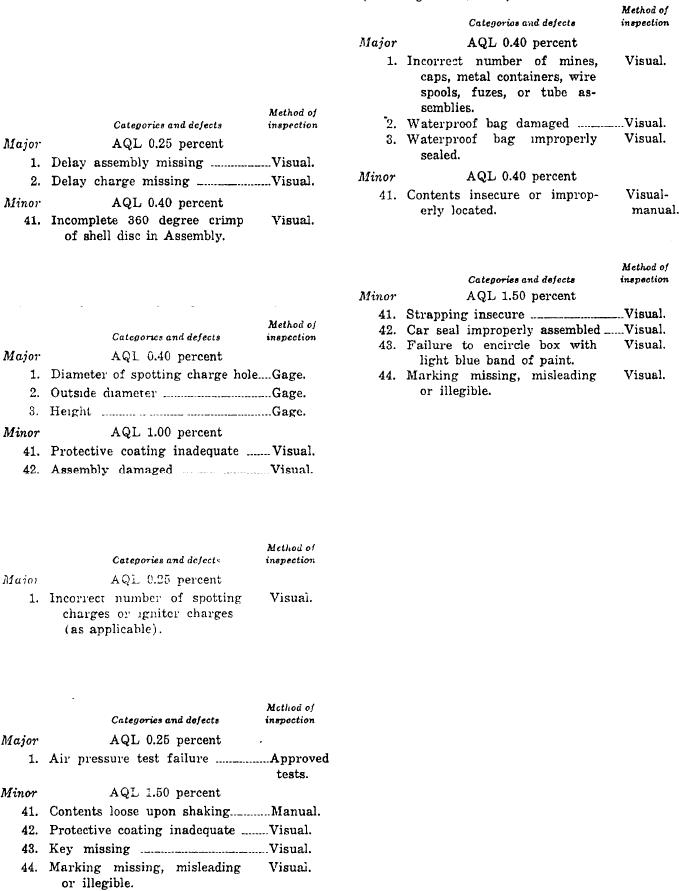

4.3.2.1.5 Box, packing (prior to seeding)

4.3.2.1 Classification of defects, Inspection

(see dwg. lV.5.48180).

of the mines shall be as indicated in the fol-

lowing subparagraphs.

4.3.2.1.1 Spotting charge assembly (see

Drawing (dwg ) 8.2-15-26 covering a detail of

Dwg. 82-0-112).

4.3.2.1.6 Box, pazking (see dwg, F7548180),

4.3.2.1.2 Tube assembly (see dwg. 82-15-

26, covering a detail of dwg. 82-0-112).

4.3.3 Test inspection. Test inspection will

be conducted as follows: The test specified

below shall be conducted by the contractor as

specified in MIL-G-2550 in accordance with

the methods specified in paragraph 4.4.

4.3.2.1.3 Container, metal, prior to sealing

(see dwg. F7548411 ) .

4.3.3.1 Functioning. Fifteen sample mines

shall be selected for the test described in

4.4.2. A retest may be made if requested by

the contractor if:

(a) No premature burst occurs (see 6.1).

(b) More than one but not more than

three duds occur.

4.3.2.1.4 Contain ers, metal (see dwg.

(c) Not more than one mine bursts at

F7548411 ).

a height of less than 6 feet above

the surface of the ground, or

(d) Not more than one mine fails to

burst at a height above 6 feet with

an audible report within 3.8 to 5.5

seconds,

Double the number of samples shall be used

in the retest. The lot will be rejected if in the

combined test and retest:

(a) A premature burst occurs (see 6.1).

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |