|

|||

|

Page Title:

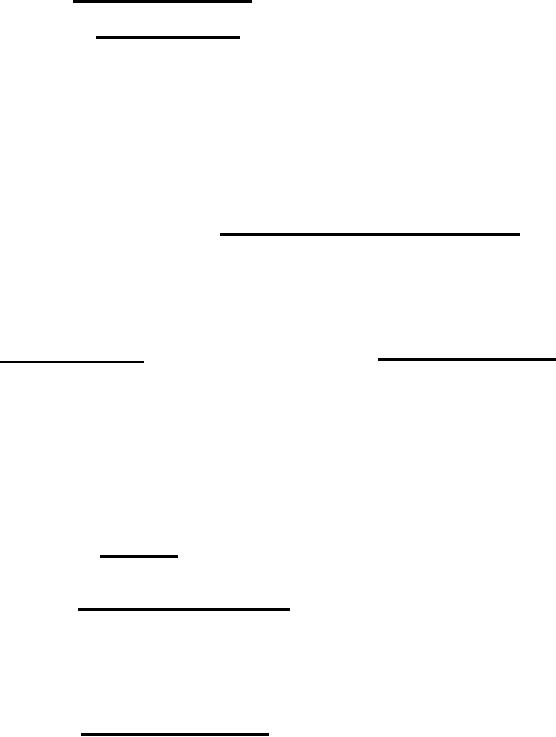

Table 1. Hydraulic Fluid cleanliness. |

|

||

| ||||||||||

|

|  MIL-M-70821 (AR)

3.3.1 Hydraulic system.

3.3.1.1 Particle size. The recoil mechanism shall be

filled with hydraulic fluid, bled, and refilled until all air

and measurable moisture are eliminated. The initial and

subsequent filling of the hydraulic system shall be with

hydraulic oil conforming to MIL-H-6083 and filtered through a 5

micron filter. Immediately after mechanical gymnastication, not

to exceed 5 minutes, a 100 ml sample of hydraulic oil shall be

taken from the lowest drain hole of each recoil cylinder.

Samples shall be drained into a suitable container. Each sample

must meet the requirements of Table I.

TABLE I.

Hydraulic Fluid cleanliness.

The water content of the hydraulic fluid shall not be more

than 0.1% as determined by standard method of test IAW ASTM

D1744. The hydraulic fluid shall be free of fforeign materials

within the following limits:

Quantity Allowed

Particle Size

no limit

below 50 microns

154

50 - 100 microns

16

101 - 200 microns

2

201 - 400 microns

Particles over 400 microns are not acceptable unless they are

fiber or lint. Only two particles of fiber or int are

acceptable, provided they do not exceed the dimensions of 40

microns in width and 3000 microns in length.

L3.1.2 Leakage. During cyclying and after all cycling, no

indication of unusual hydraulic leakage shall OCCUr .

3.3.2 Surface cleanliness. All finish machined surfaces

shall be free of condensation or other foreign residues from the

time of final machining until final assembly. All parts and

assemblies being assembled into the completed mount shall be

free of all foreign material after assembly. Assembly shall be

performed in the controlled environment specified in 6.3.

3.3.3 Part modification. No parts shall be altered or hand-

fitted during assembly unless such modification has been

authorized by an approved drawing change, or is authorized by

instructions presently listed on the drawings.

4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |