|

|||

|

Page Title:

Table I. -- Malfunctiom, nonacceptable conditions, and broken parts |

|

||

| ||||||||||

|

|  MIL-R-3285

nent, and without malfunction, in excess of

4. SAMPLING, INSPECTION, AND

the limits shown in table I.

TEST PROCEDURES

4.1 General procedures and inspection.

3.11 Workmanship. -- Finished rifles shall

be free of defects which may affect service-

4.1.1 Sampling.

ability, functioning, operation, or appearance.

4.1.1.1 Lot.--un}ess otherwise specified, 8

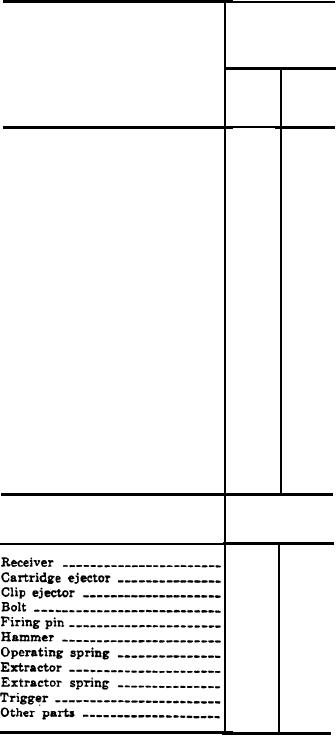

TABLE I.--Malfunctiom, nonacceptable con

lot shall consist of not more than 500 rifies

ditions, and broken parts.

or 500 of each spare part.

Number per-

4.1.2.2 Size of sample The size of the

mitted in the

inspection sample shall consist of the entire

endurance test

Malfunctions and nonacceptable

lot The size of test sample shall be as speci-

conditions

First Second

fied under each test.

3,000 3,000

rounds rounds

4.1.2 Inspection and tests, general.

Failure of trigger to release (any

4.1.2.1 Place. -- Unless otherwise speci-

cause)

0

0

fied, inspection and tests shall be conducted

Failure to Close (due to any rifle

by a Government inspector at the place of

component) ------------------

3

5

Failure to eject cartridge case----

0

0

manufacture. The inspector may subject all

Failure to eject chip _______

1

1

or part of any lot of components or assem-

Failure to extract (bolt remains

blies to such inspection as he deems necessary

closed )

0

0

to determine compliance with this specifica-

Failure to feed (insufficient recoil)

4

2

tion.

Failure to stay open on last round.

0

0

Follower fails to function____

0

0

4.1.2.2 Contractors inspection.-The con-

Hangfire (noticeable). (See

4.12.4.1.

)

tractor shall maintain an adequate system of

0

0

Loose barrel and receiver _____

processing, inspection, and lot identification.

Loose

stock

0

0

Only such lots which meet the requirements

Misfire. (See 4.1.2.4.1.) --------

0

0

of this specification shall be submitted for

Pierced primers (due to excessive

final Government inspection.

protrusion or roughness) ------

0

0

0

0

Safety fails to function _____

4.1.2.3 Concurrent tests. -- The targeting

Worn clip latch -----------------

0

0

Worn cylinder (causing gas leak)

0

0

test and the accuracy test may be fired con-

Breeching space max. 0.002 in.

currently at a range of 100 yards.

crease in 6,000 rds. --------

0

0

4.1.2.4 Reinspection and retests.

Broken or unserviceable parts

4.1.2.4.1 Hangfires and misfires.-If hang-

fires and misfires occur during any of the

0

0

tests, the rifle shall be subjected to the firing

1

0

pin indent test; and in the event that the

0

0

firing pin blow is not within the specified

0

0

limits, the rifle shall not be accepted until

0

1

properly corrected.

0

0

0

0

4.1.2.4.2 Defective ammunition. -- Mal-

1

0

0

0

functions in any test traceable to defective

0

0

ammunition shall not be counted against the

0

2

rifle being tested.

5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |