|

|||

|

Page Title:

Sampling for Quality conformance inspection |

|

||

| ||||||||||

|

|  MIL-S-24686A(SH)

4.4.2 Inspecti on lot. For the purpose of quality conformance inspection and

test sampling, a lot is defined as all the sprinklers of the same material, type,

style, size, and temperature rating produced in one facility using the same

production processes and offered for delivery at the same time. All sprinklers in

the lot must have been manufactured within the preceding 12 months. For the

purpose of quality conformance inspection and test sampling of frangible bulbs, a

lot is defined as all bulbs of the same material, type, style, and temperature

rating produced in one facility and delivered at the same time.

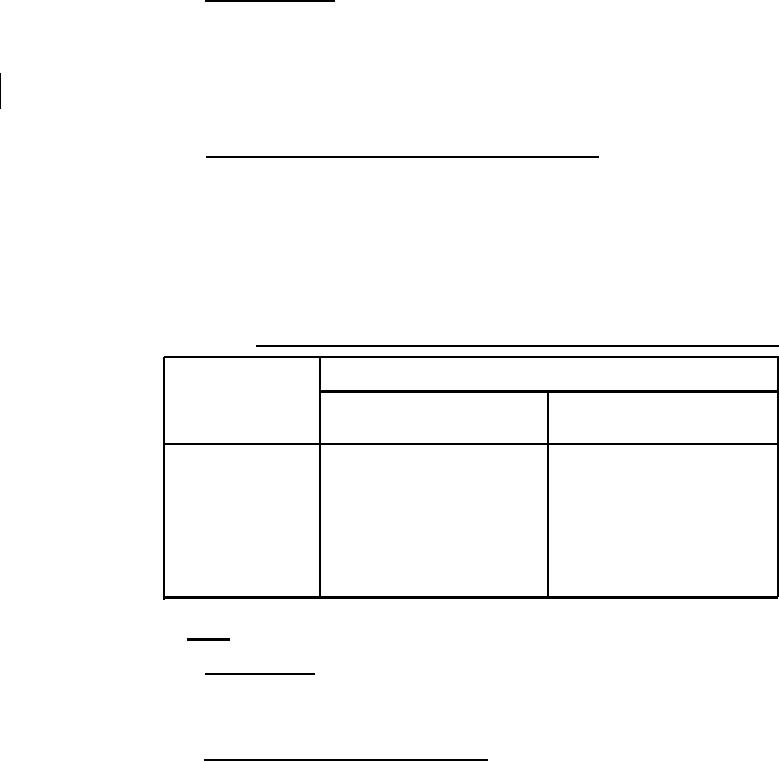

4.4.3 Sampling f or Quality conformance ins pection . As a minimum, the

contractor shall randomly select a sample quantity from each lot of completed

sprinklers in accordance with tables V and VI and inspect them in accordance with

4.4, 4.5.1 and 4.5.2. Sample size depends on the sampling plan code letter shown

in table V. If one or more defects are found in any sample, the entire lot shall

be rejected. The contractor has the option of screening the lot 100 percent for

the defective characteristic(s) or providing a new lot which shall be inspected in

accordance with sampling plan contained herein. The contractor shall maintain for

a period of 3 years after contract completion records of inspections, tests, and

any resulting rejections.

Sample size for Quality conformance insp ect ions an d tests.

TABLE VI.

Sample size

Sampling plan

Sampling plan

code letter B

code letter A

Lot size

ALL

ALL

1-8

8

ALL

9-20

8

20

21-90

12

20

91-150

19

20

151-280

47

21

281-500

27

47

501-1200

35

53

1200-OVER

4.5 Tests.

4.5.1 Leakage test. Each sample shall be subjected to a leakage test to

determine compliance to 3.5. The pressure shall be increased to 500 psig and held

for 1 minute. During this test, there shall be no weeping or leakage. Test shall

be conducted using clean fresh water.

4.5.2 Operating temperature bath test. Each sample shall be subjected to a

test to verify the actuating temperature range to determine compliance with 3.5.

The test shall be performed in accordance with the requirements of the ANSI/UL 199

operating temperature bath test, except that the frangible bulbs (as opposed to

the assembled sprinklers) may be tested.

10

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |