|

|||

|

|

|||

| ||||||||||

|

|  MIL-T-62145E

Not less than 4 additional full width crossmembers on class C vehicles and not less than

5 additional full width crossmembers on class D and E vehicles shall be provided in the area of

the rear bogie. The additional crossmembers may be joined by welding to the normally located

crossmembers in the rear bogie area. Crossmembers shall be reinforced by gusset plates or

brackets at points of attachment to longitudinal sills. Contact edges of crossmembers with

longitudinal sills, and contact edges of welded reinforcements shall be welded for not less than

50 percent of the edge length. Longitudinal sills shall be constructed of structural steel channels

or formed channels. Formed channel sills shall be reinforced within the sill, at each

crossmember or body mounting point, with formed channel reinforcements. Frame members

shall be of a continuous length without splices or joints.

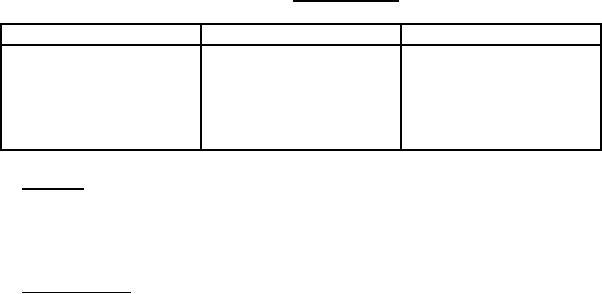

TABLE IX. Framing gages.

Designation

US Standard gage No.

Equivalent inches

Crossmembers

10

0.1345

Side and end rails

10

0.1345

Longitudinal sills

8

0.1644

Reinforcements

8

0.1644

Rack posts

11

0.1196

* 3.6.3 Flooring. Flooring shall be safety steel tread plate not less than 1/4 inch in thickness

exclusive of the projections. A medium tread plate pattern shall be furnished. When the body

floor is constructed in two or more pieces, continuous seam welds having full penetration shall

be provided the full length of each seam.

* 3.6.4 Front bulkhead. A full-width removable front bulkhead shall be furnished. The

bulkhead shall be not less than 42 inches in height, measured from the platform floor. The

bulkhead shall be formed or reinforced for rigidity. The bulkhead shall be provided with a

screen window in alinement with the rear window of the truck cab. The screen shall be

corrosion-resistant, of not more than No. 6 mesh, number 20 wire, having a square opening of

0.132 inch. The screen shall be enclosed in a metal frame and secured by screws to the

bulkhead. The screen window shall be covered on the inside with a No. 2 mesh, number 16 wire,

having a square opening of 0.437 inch. The bulkhead stakes shall be on the outside of the

payload area and shall be bolted to the bulkhead. The bulkhead shall be secured in stake pockets

and to the side sections with draw-down type fasteners. Openings for the chassis mounted winch

line or body mounted winch hydraulic lines, if a winch is furnished, shall be provided. The

bulkhead shall be capable of withstanding a horizontal static load equal to one half the payload

capacity of the vehicle without permanent distortion of the bulkhead or its mountings.

32

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |