|

|||

|

|

|||

| ||||||||||

|

|  MIL-V-15508B

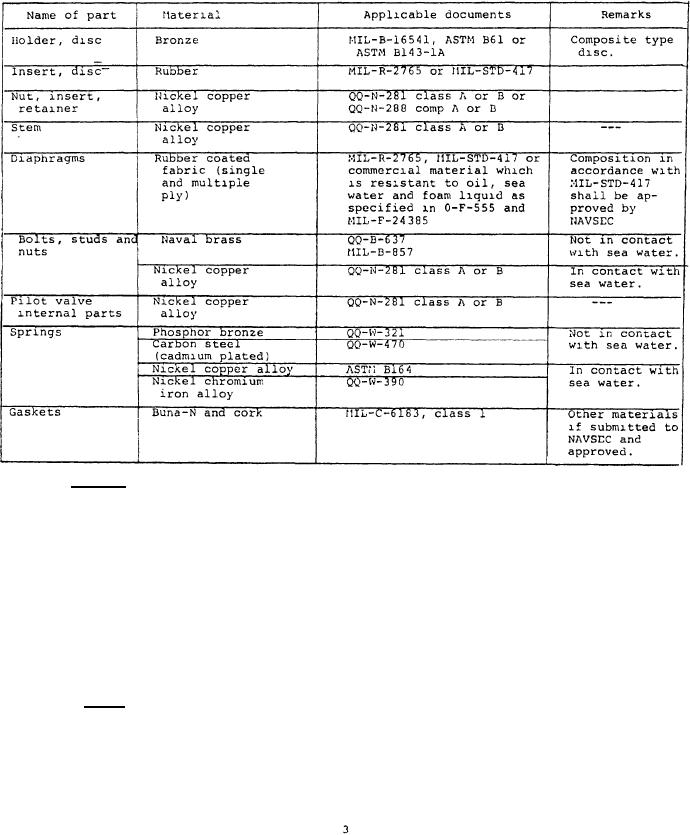

Table I - Materials (Cont'd).

3.3 Design. The valves shall be of the globe (type I) or angle (type II) type main

valve, controlled by a pilot valve employing the fluid flowing through the main valve to

rapidly (not more than 2 seconds maximum) open or close the main valve. The movement of the

main valve disc shall be positively actuated by the movement of a rubber diaphragm when it

is subjected to fluid pressures from 50 to 250 p.s.i. while controlling fluid in a similar

range of pressures. Diaphragms shall not be used as a disc or seating element. Weight and

size of the assembled unit shall be kept to a minimum.

3.3.1 A pilot control valve of a multiple port design shall be furnished to provide

for the quick opening and closing of the main valve, and shall be operable with electrical

or mechanical operating mechanism (see 3.3.12) .

3.3.2 Valves shall be so designed and constructed that failure of the diaphragm will

cause the valve to remain open,

3.3.3 The design of all valves shall be such as to afford easy access for adjustment

and repair without removal from the line.

#

3.3.4 Body. The main valve body shall be designed for class A 150 or class B 250

p.s.i. fluid service. Hydrostatic (water) test pressure shall be as follows:

Class A - 150 p.s.i. service - 225 p.s.i. hydrostatic test,

Class B - 250 p.s.i. service - 375 p.s.i. hydrostatic test.

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |